Pūnaewele:www.welding-honest.com Whatsapp:+86 13252436578

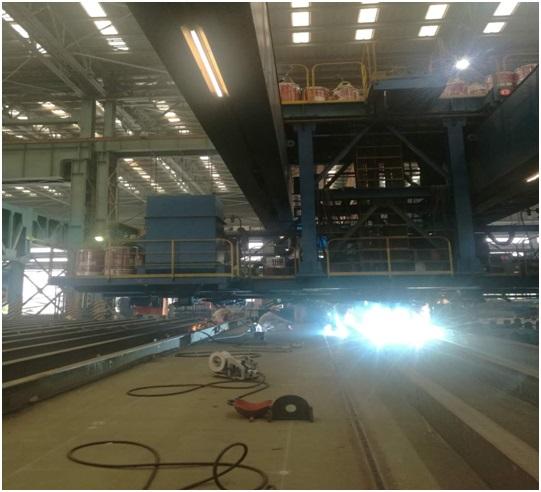

I ka hana kuʻi ʻana o ka hana moku, nā alahaka, nā hale kila a me nā ʻoihana ʻē aʻe, he pinepine ka lōʻihi o ka ʻaoʻao ʻākau i hoʻohana ʻia, a hoʻohana pinepine ʻia ka wili ʻana, me nā trolleys welding, nā lima kuʻi lima a ʻoi aku ka maikaʻi.No ka T-row multi-electrode welding, ua hoʻokumu kā mākou hui i ka GFL-70C iron powder type flux cored wire me GCL-11G metal powder type welding wire, i ʻae ʻia e nā mea kūʻai aku.He kiʻekiʻe ke kiʻekiʻe o ka wiliwili ʻana o kēia ʻano hoʻohui kuʻi, ʻoi aku ka maikaʻi o ka zinc powder-resistant primer, a me ka hoʻokumu ʻana o ka weld bead nani.ʻO ka pono o ka deposition o ka uea mua GCL-11G he kiʻekiʻe e like me 97%, ma muli o ka nui o ka metala filler, a ʻo ka uea hope GFL-70C e hōʻoia i ka hoʻokumu ʻana o ka weld bead, a hiki i ka wikiwiki welding ke hiki i 1000-1400mm /min.He mea kūpono ia no ka hoʻopili paʻa ʻana a me ka hoʻoheheʻe ʻana i nā ʻano like ʻole e like me nā moku, nā alahaka, nā mīkini, nā kaʻa a me nā hale kila.

Nui-electrode T-lālani kiʻekiʻe-wikiwiki a me ka pono wiliwili

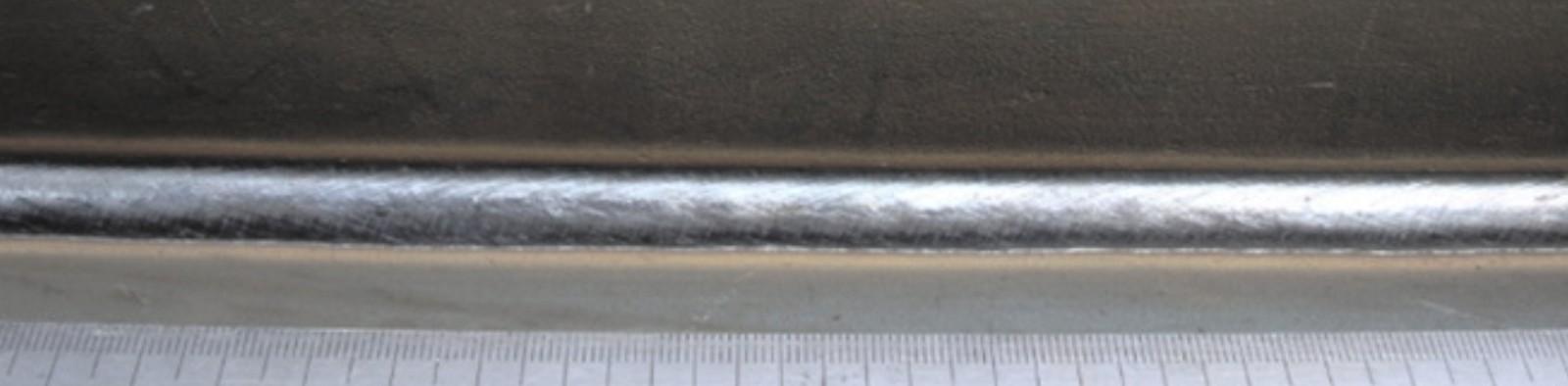

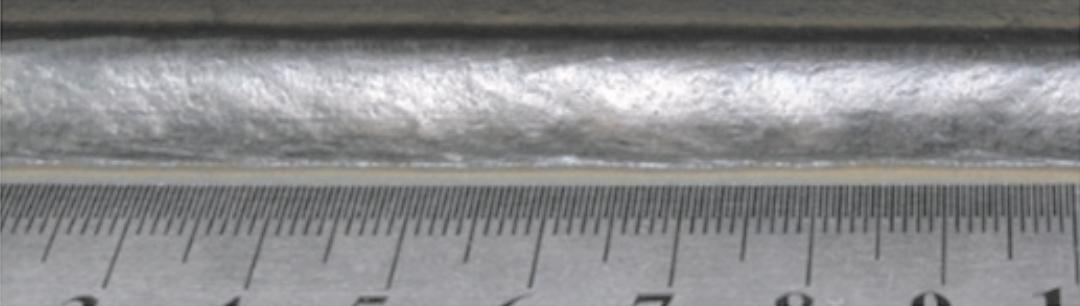

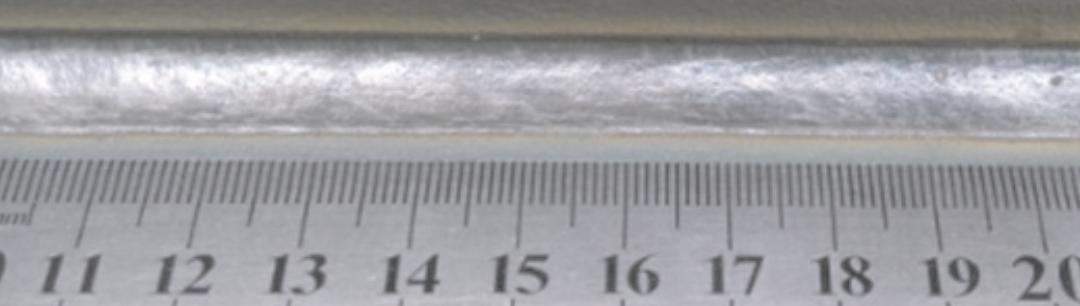

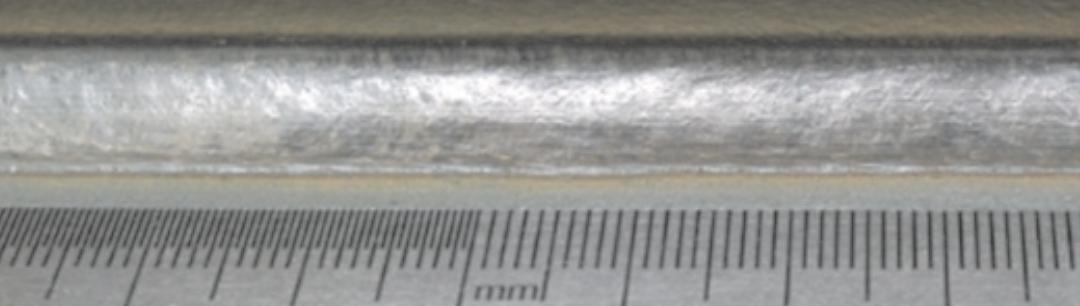

ʻO ke ʻano o ka weld slag wehe

Ma mua o ka wehe ʻana

Ma hope o ka wehe ʻana

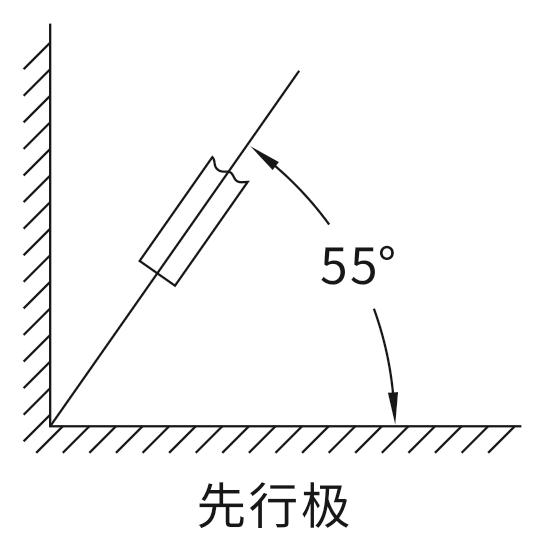

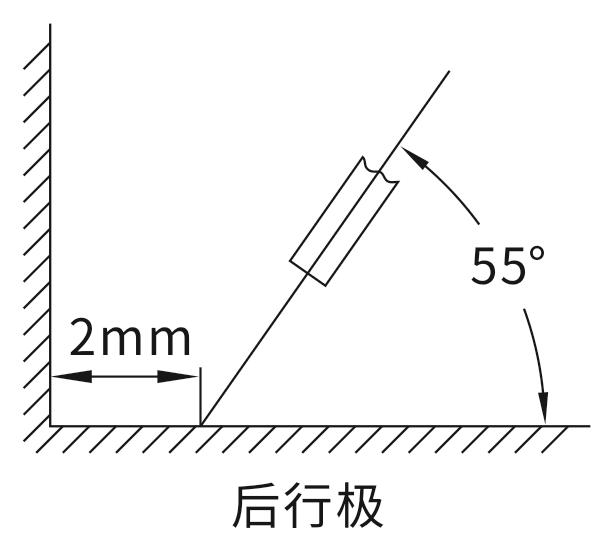

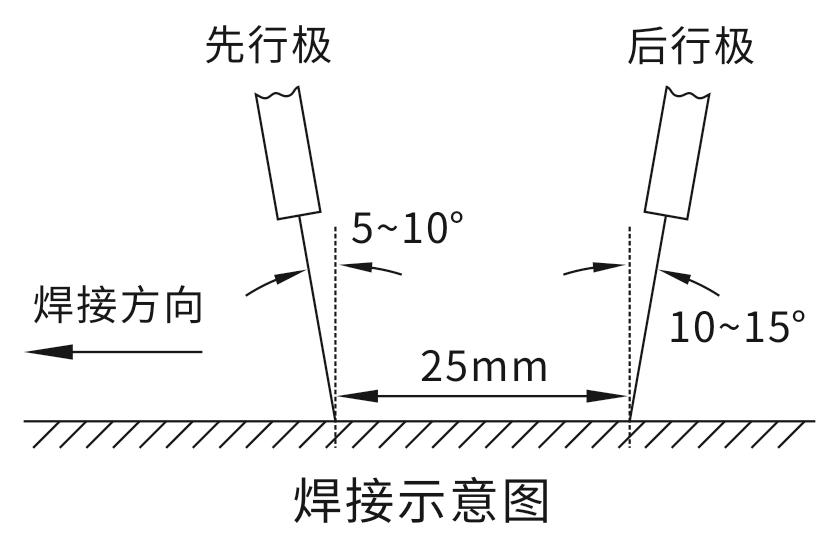

ʻO ka hiʻohiʻona nui loa o kēia ʻano hana kuʻi ʻana ʻo ia kona kiʻekiʻe kiʻekiʻe, multi-electrode welding i ka manawa like, a ʻaʻohe pono e hopohopo e pili ana i ka interference o ka polarity a me ka māla magnetic.Loaʻa i kēlā me kēia hui o nā welds ʻelua ʻelua mau kukui wili, a ʻo kēlā me kēia hui he mau uwea mua a ma hope.ʻOi aku ka maikaʻi o ke kūpaʻa porosity o ka uea mua a lawelawe ʻo ia ma ke ʻano he nui o ka metala filler.Pono ka uwea hope e hōʻoia i ka hana ʻana o ka weld bead i pālahalaha, ʻaʻahu a maʻemaʻe.ʻO nā hiʻohiʻona o ka pauka hao ʻano flux cored wire, e like me ka uea hope o kēia hui ʻana, hiki ke hoʻokō i nā koi o kona ʻano like a me kona helehelena.Hōʻike ʻia ke kiʻi ma lalo nei ke kihi o ka lama kuʻi a me ka hoʻoponopono ʻana i ka mamao o kēia ʻano kuʻi.

Hybrid kiʻekiʻe kiʻekiʻe kiʻekiʻe kiʻekiʻe fillet welding:

'Ōlelo Aʻo: E hoʻololi i ka mamao ma waena o nā uwea mua a me hope e like me ka wela maoli o ka loko i hoʻoheheʻe ʻia i ka wā wili.

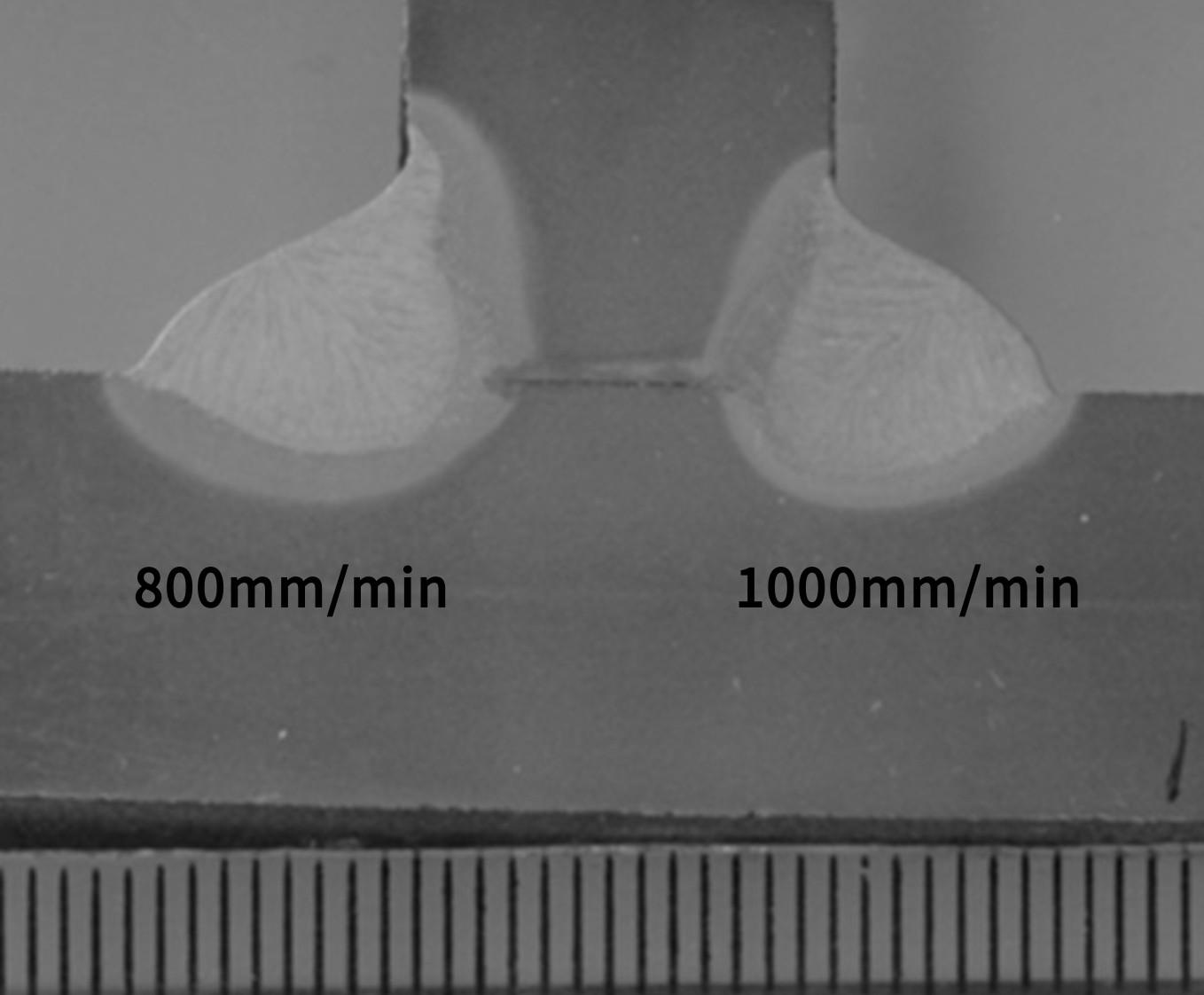

Hiki i kēia ʻano hoʻoheheʻe ke loaʻa i ka manaʻo wili i makemake ʻia ma o ka hoʻoponopono ʻana i nā ʻāpana welding ʻokoʻa.Ma ka hoʻololi ʻana i ke au o ka welding, ka uila, ka wikiwiki o ka welding, ka mamao o ka lama welding, etc.

Hoʻohui ʻia i ka laʻana 1

GCL-11G (hoʻokiʻekiʻe kiʻekiʻe)/GFL-70C (hope electrode) 1.4mm:

| ʻO kēia a me ka uila | wiliwili māmā mm/min | Solder wāwae lōʻihi |

| Paionia 360A/32V Papa hahai 360A/38V ʻO ka mamao uila 25MM | 800 | 9-10 |

| 1000 | 7-8 |

| wāwae lōʻihi | 9.0 | wāwae lōʻihi | 7.0 | |

| Huipuʻu | 0.4 | Huipuʻu | 0.8 | |

| Ke komo ʻana | 2.0 | Ke komo ʻana | 2.2 |

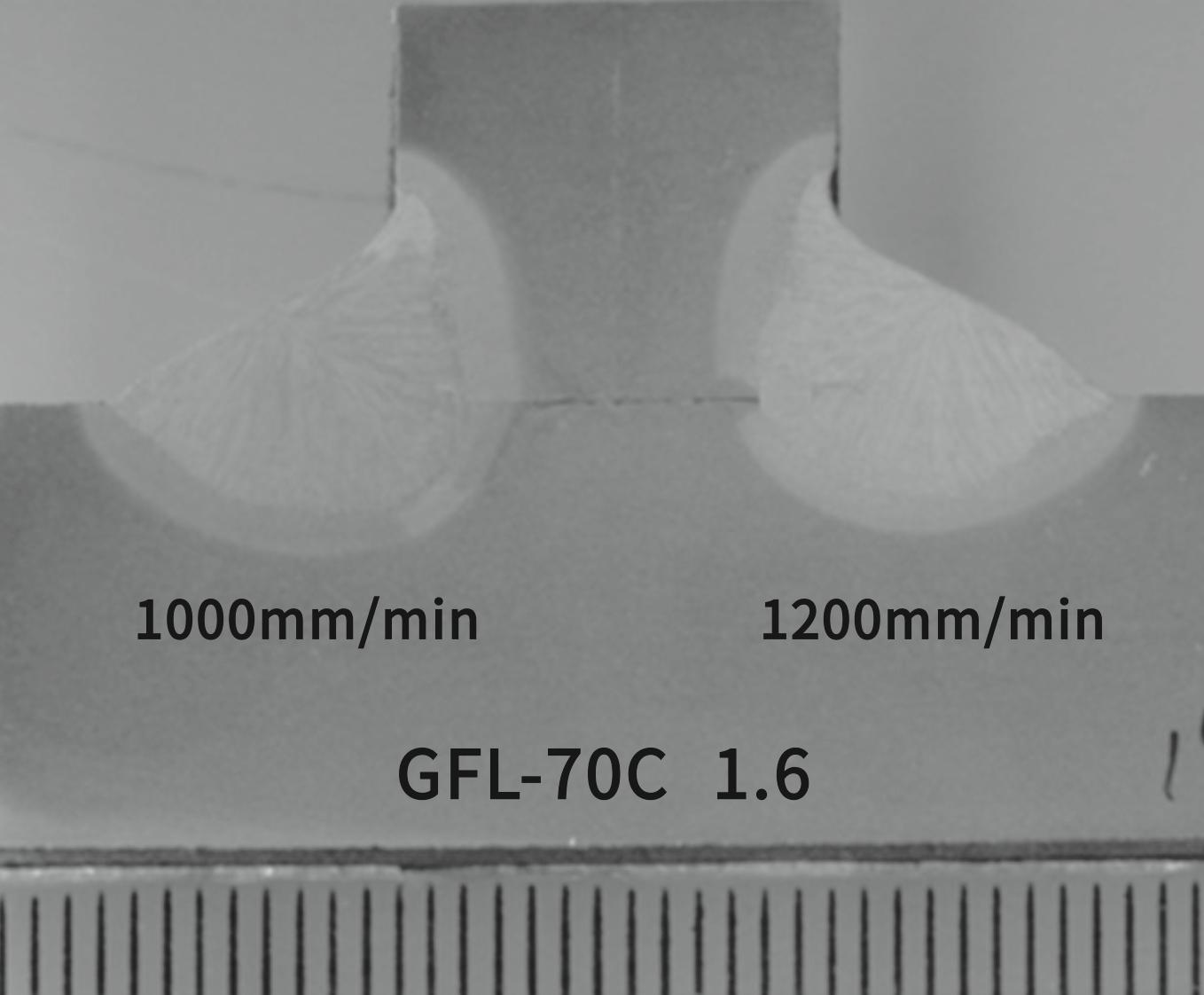

Hoʻohui ʻia ka laʻana hoʻoheheʻe fillet wikiwiki loa 2

GCL-11G (hoʻokiʻekiʻe kiʻekiʻe)/GFL-70C (hope electrode) 1.6mm:

| ʻO kēia a me ka uila | wiliwili māmā mm/min | Solder wāwae lōʻihi |

| Paionia 360A/32V Papa hahai 360A/38V ʻO ka mamao uila 25MM | 1000 | 8-9 |

| 1200 | 7-8 |

ʻIke komo

| wāwae lōʻihi | 8.0 |

| wāwae lōʻihi | 7.0 |

| Huipuʻu | 0 | Huipuʻu | 0.3 | |

| Ke komo ʻana | 2.4 | Ke komo ʻana | 2.7 |

ʻO GCL-11G+GFL-70C ka manaʻo hoʻoheheʻe kūlana

| Māhele wiliwili | Hōʻike mm | wiliwili kikoʻī | wiliwili māmā mm/min | Ka nui o ka wāwae solder mm | ʻŌlelo | |

| Kilika mua | Kilika hope | |||||

| hui ʻana | 1.4 | 350-400A 32-36V | 320-380A 36-38V | 700- 1000 | 5-8 | ʻO ka uea mua ʻo GCL-11G, hoʻohana nui ʻia no ka hoʻopiha, kiʻekiʻe o kēia manawa, haʻahaʻa haʻahaʻa;ʻo ka uea hope he GFL-70C, ka uila kiʻekiʻe, ka haʻahaʻa o kēia manawa |

| 1.6 | 360-420A 36-38V | 320-400A 36-38V | 1000- 14000 | 5-8 | ||

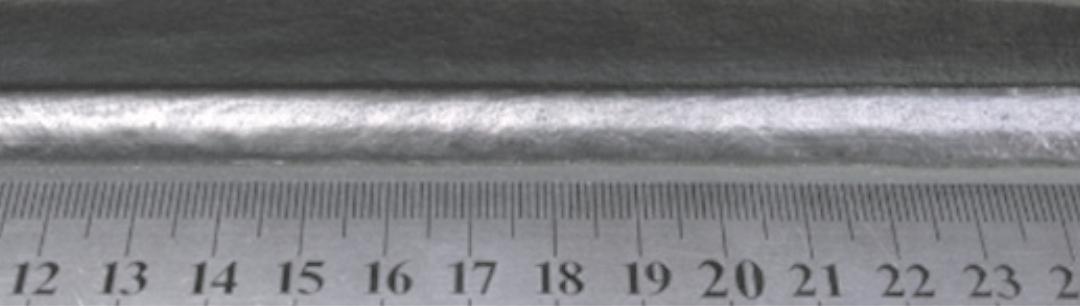

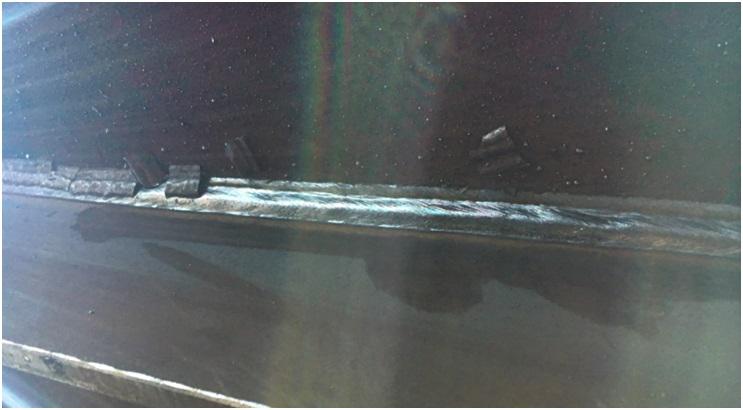

ʻO kekahi: 9-12mm hiki ke hoʻokō ʻia ma ka hoʻoponopono hou ʻana i ke kihi wiliwili kikoʻī kikoʻī a me ka wikiwiki wili.Weld bead e like me ka mea i hōʻike ʻia ma lalo nei:

12mm nui wiliwili kihi

No kēia ʻano hana hoʻoheheʻe, e ʻoluʻolu e hahai i nā ʻōlelo aʻoaʻo a me ka mālama ʻana

1. E hoʻomaʻemaʻe i ka ʻōpala o ka ʻili, ka ʻōpala, nā ʻili ʻaila, a me nā koena hoʻoheheʻe ʻana, inā ʻaʻole hiki ke hoʻoulu ʻia nā pores a i ʻole nā pōʻino e like me ka hoʻoheheʻe maikaʻi ʻana.

2. ʻO ka nui o ka wai mahu e hoʻopilikia i ka maikaʻi o ka wiliwili ʻana a me nā pores.Inā kiʻekiʻe ka haʻahaʻa, pono e hana ʻia ka dehumidification kūpono ma mua o ka wili ʻana, a e pale ʻia ka wili ʻana i ka pō hoʻokahi ʻaoʻao.

3. Hoʻomaluʻia ka mānoanoa o ka kiʻi pena ma 15-35um.Inā mānoanoa loa ka mānoanoa o ka pena kiʻiʻoniʻoni, e maʻalahi ia i nā pores, a pono e hoʻoliʻi ʻia inā pono.

4. Hoʻomaluʻia ka holoʻana o ke kinoea ma 20-25l / min, e hoʻomaluʻia ka elongation maloʻo ma kahi o 20 ~ 25mm, aʻoi aku ka wikiwiki o ka makani ma mua o 2m / s, a pono ka hale e pono ai.

5. I ka hui pu ana:

(1) Na ka uea mua GCL-11G welding power panel e koho i ka mea pa'a, a na ka uea hope GFL-70C welding power panel e koho i ka mea nui;

(2) I ka welding welds fillet, lawe ʻia kēlā me kēia hui o quadrupoles ma ke ʻano e kū pono ai kekahi i kekahi me nā uwea mua a me hope.

ʻO ka mea i luna nei no ka ʻike wale nō, e ʻoluʻolu e hoʻomālamalama mai iaʻu inā he mea kūpono ʻole.

More information send E-mail to export@welding-honest.com

Ka manawa hoʻouna: Dec-20-2022