Hoʻohana ʻia ka hale kiaʻi no ka distillation, hoʻomaʻemaʻe, absorption, distillation a me nā mea kemika ʻē aʻe, ʻo ka hapa nui o nā mea hale kiaʻi e pono e hoʻopili i ka waika, alkali, paʻakai, nā mea hoʻoheheʻe organik a me nā media corrosive ʻē aʻe, no laila pono e hoʻokuʻu i kahi ʻāpana nui o ka corrosion resistant layer. i loko o ka cylinder a me nā ʻāpana hoʻopaʻa.Ma ke ʻano he ala kūpono o ka hoʻoulu ʻana, hoʻohana nui ʻia ka strip surfacing i ka wiliwili hale kiaʻi o nā mea hana kemika.

ʻO ka ʻenehana hoʻoheheʻe electrode kuʻuna he ʻenehana hoʻoheheʻe ʻana i ke arc submerged submerged me ka papa hoʻololi a me ka papa pale pale corrosion, akā ua lōʻihi kēia ʻenehana i ka pōʻai hana a me ke kumu kūʻai kiʻekiʻe.I mea e hoʻoponopono ai i kēia pilikia, ua hoʻomohala ʻo JingQunCo i nā mea hoʻoheheʻe hoʻoheheʻe hoʻokahi-layer (GDS-309LA welding strip, GXS-ED308L electroslag flux), hiki ke hoʻokō i ka hopena o ka ʻili ʻelua ʻāpana me ka ʻili hoʻokahi wale nō, a hiki ke maʻalahi. ke kaʻina hana ʻili mai ka papa ʻelua i ka ʻili ʻana i hoʻokahi.

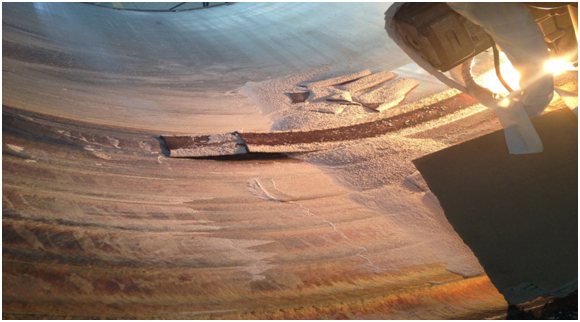

ʻO ka hoʻolauna ʻana i nā mea wili

1. ʻO ka ʻāpana Chemical

| Rules/Inoa | C | Si | Mn | P | S | Cr | Ni | Note |

| NB/T47018.5 EQ309LA | ≤0.030 | ≤1.00 | 0.5-2.5 | ≤0.025 | ≤0.015 | 21.0-23.0 | 9.0-12.0 | kāʻei kūʻai |

| GDS-309LA | 0.018 | 0.34 | 1.90 | 0.017 | 0.001 | 21.96 | 11.17 | kāʻei kūʻai |

| Rules/Inoa | NB/T47018.5 FZ308-D | GDS-309LA+GXS-ED308L kāʻei kūʻai + hui ʻana o Flux | |||

| C | ≤0.05 | 0.028 | 0.028 | 0.029 | 0.029 |

| Si | ≤1.00 | 0.58 | 0.64 | 0.62 | 0.64 |

| Mn | ≤2.5 | 1.33 | 1.33 | 1.35 | 1.33 |

| P | ≤0.030 | 0.018 | 0.018 | 0.018 | 0.017 |

| S | ≤0.020 | 0.004 | 0.004 | 0.004 | 0.004 |

| Cr | 18.0-21.0 | 18.21 | 18.47 | 18.39 | 18.28 |

| Ni | 8.0-11.0 | 10.12 | 10.31 | 10.27 | 10.30 |

| Nānā | metala waiho ʻia | ʻili wiliwili | Ma lalo o ka ili 1mm | Ma lalo o ka ili 2mm | Ma lalo o ka ʻili 3mm |

2.Weld helehelena

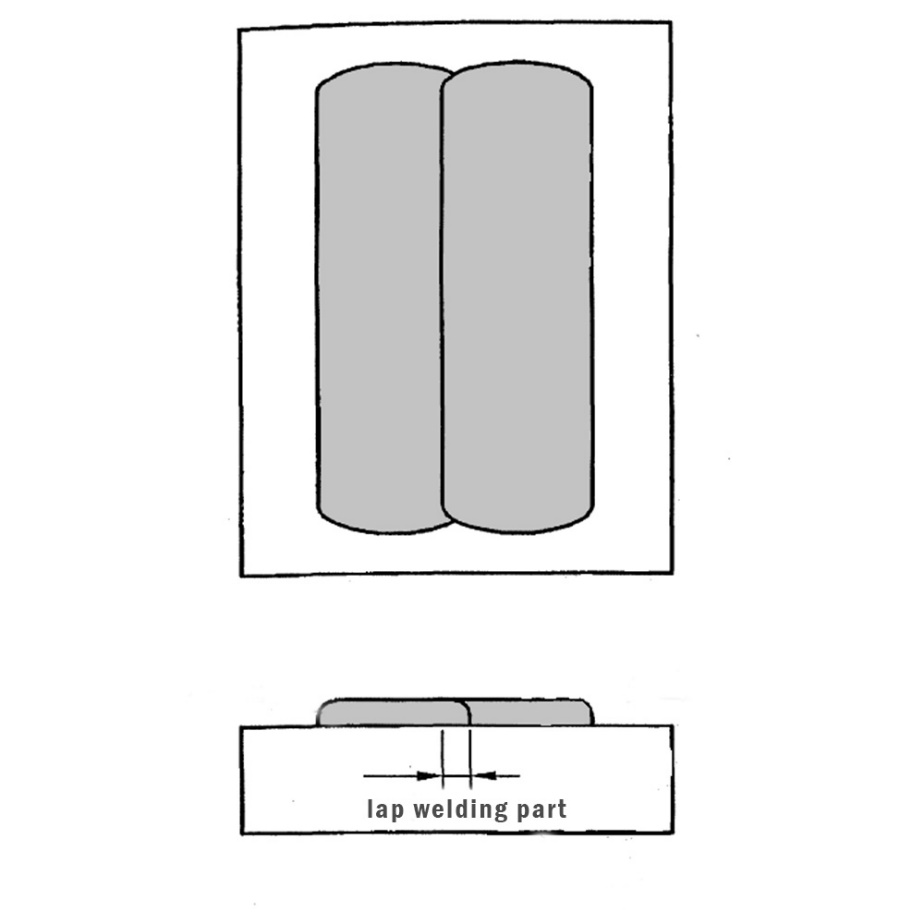

Paipai ʻia nā ʻāpana wili

| Hōʻike (mm) | 0.5*60 |

| Uila(A) | 850-950 |

| Voltage(V) | 26-30 |

| Wka māmā holo (mm/min) | 150 |

| Lka lōʻihi (mm) | 35-40 |

| Kuʻi wāwae (mm/min) | 6-10 |

| ʻO ka mānoanoa o ka laha ʻana (mm/min) | Apili 25 |

Weld pass mānoanoa: ma kahi o 4.7mm

Weld laula: ma kahi o 62.5mm

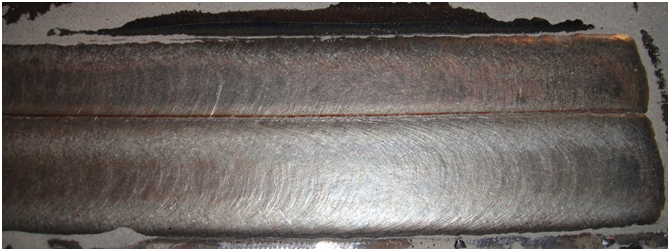

Weld pass hiʻohiʻona: nani ke ʻano, weld ʻili palahalaha, maʻemaʻe ka hoʻololi ʻana.

3.Mechanical mana

ʻO ka maʻiʻo ferrite (ke kūlana welded)

| Hoʻohui ʻia i ke kaula hao + Flux | GDS-309LA+GXS-ED308L |

| Ana waiwai | ʻO ka maʻiʻo ferrite e pili ana i 7FN, a ʻo ka pākēneka ferrite ma kahi o 8% |

| Ana kūlana | Weld ili |

ʻO ke ala hoʻāʻo: GB/T 1954-2008 "chromium-nickel austenitic stainless steel weld ferrite content method ana ana"

Hoʻāʻo piʻo:

as

620℃*20h

Nā hualoaʻa hoʻāʻo: kūlou ʻaoʻao, anawaena indenter 4T (40mm), kihi kihi 180° me ka māwae ʻole.

ʻO ka hoʻāʻo corrosion intergranular

E like me ka welded

620℃*20h

Kaʻina hoʻāʻo: GB/T 4334-2020 Kaʻina E

ʻO ka hopena ho'āʻo: keleawe - keleawe sulfate -16% sulfuric acid

Nā hualoaʻa hoʻāʻo: ʻAʻohe māwae corrosion intergranular

Micro metallography o ka papa i luna

E like me ka welded

E like me ka welded

620 ℃ * 20h mālama wela

620 ℃ * 20h mālama wela

Ke noi ʻenekinia

1.Customer welding kaʻina loiloi kaʻina hana

2.Customer kahua kūkulu

Ma hope o nā makahiki o ka noiʻi a me ka hoʻomohala ʻana, ʻo Jingqun hoʻokahi-layer electroslag surfacing welding material hana paʻa a hilinaʻi hoʻi, he nui nā hoʻokō ʻenehana noiʻi.

Welina mai nā mea kūʻai aku e kūkākūkā a koho!

ʻIke hou aku e hoʻohui iā whatsapp+86 13252436578

E-Mail:sale@welding-honest.com

Ka manawa hoʻouna: Nov-04-2022