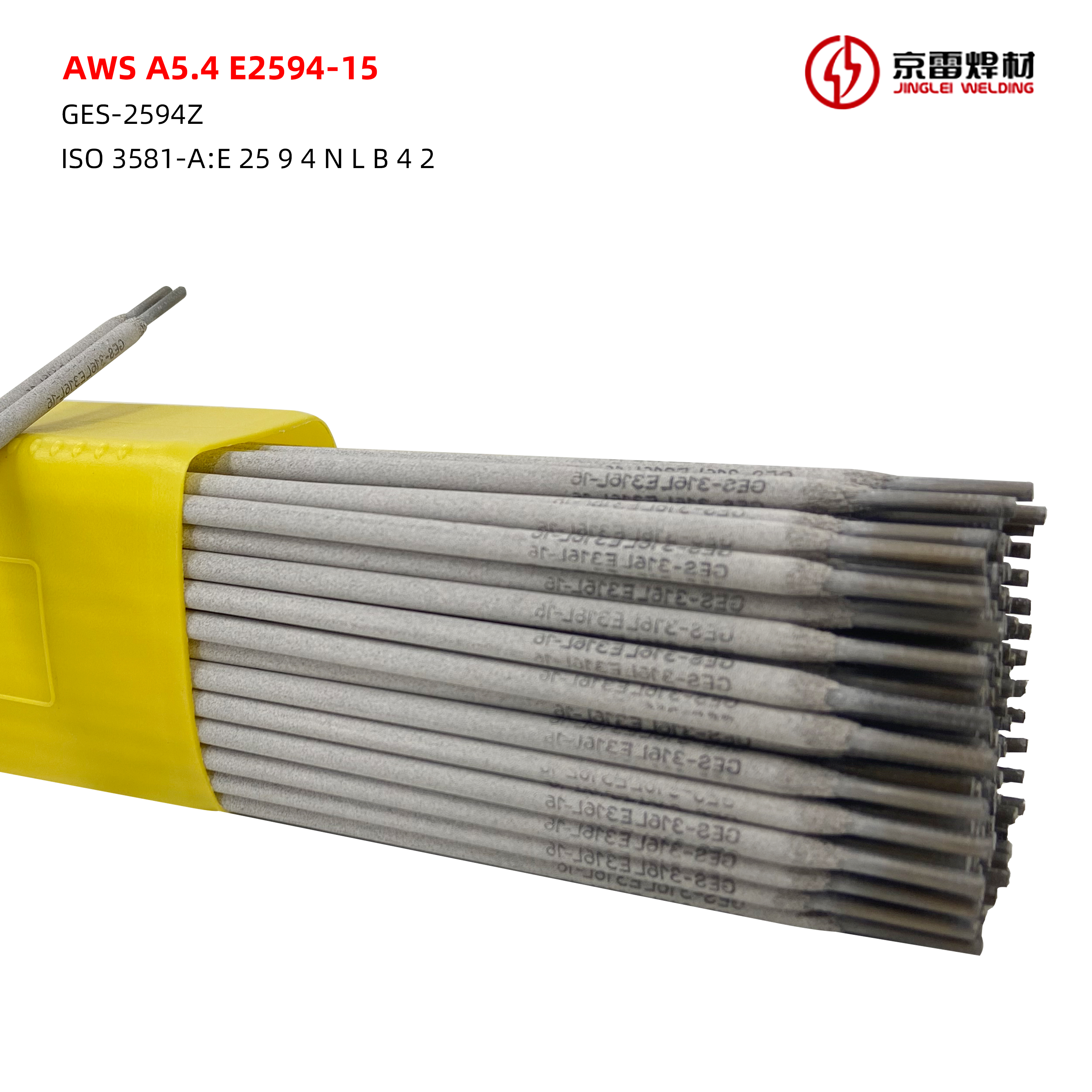

Electrode Manual E2594-15 GXHY methanol dehydration tower electrode

IKE NUI WELDING

Mai ʻae i nā nīnau

E hoʻomau mau iā ʻoe

Paʻa ʻole ʻo Arc

ʻO ka hoʻoheheʻe ʻana

ʻO ka pipiʻi nui

He kūpono no ke kuʻi ʻana o ke kila kuhili ʻole duplex

loaʻa iā 25% Cr, e like me 0022 crni7mo4n03cr25ni6mo3cu2n, etc.

ʻO ka haʻahaʻa hydrogen pālua ʻelua ʻāpana lima kila kila, ʻo ka mea nui ʻo 25.5Cr-10Ni-4Mo-0.25N

Maikaʻi ka ripple

ʻO ka weld metala he austenitic a me ka ferritic biphase

hale, a ʻo ka papa kuhikuhi kūʻē corrosion ʻo PRE>40

Loaʻa iā ia ka ikaika kiʻekiʻe a me ke kūpaʻa maikaʻi i ka pitting a me ke koʻikoʻi o ka corrosion crack.

ʻOi aku ka maikaʻi o ka wiliwili ʻenehana, kūpaʻa arc, nani ka hana ʻana, ʻoluʻolu ripple, liʻiliʻi liʻiliʻi, maʻalahi ka wehe ʻana i ka slag.

ʻO ka slagging maʻalahi

Laina Huahana

KOMPONO KIMIKA:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | 'ē aʻe |

| GB/T RULA | 0.033 | 1.05 | 0.76 | 0.019 | 0.011 | 9.1 | 25.5 | 3.9 | 0.11 | N:0.24 |

WAIWAI MECHANICAL:

| WAIWAI | IKAIKA HUA(MPa) | KA IKAIKA HOU (MPa) | KA WAIWAI IMAPACT J/℃ | Hana wela °C*h | ||||

| GB/T RULA | 918 | 22 | - | - | ||||

PALAPALA PALAPALA I MANAOIA:

| NĀ KĀNĀWAI (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| UILA (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Kākoʻo hale hana

He kūpono ka huahana no kahi

laulā o nā noi

IKE NUI WELDING

-

Nā mea wiliwili no nā kaʻa kaʻaahi

Harbin uila ʻekolu puka CMT

-

CJ50 pahu pahu

KOMPONO KIMIKA:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | 'ē aʻe |

| GB/T RULA | 0.033 | 1.05 | 0.76 | 0.019 | 0.011 | 9.1 | 25.5 | 3.9 | 0.11 | N:0.24 |

WAIWAI MECHANICAL:

| WAIWAI | IKAIKA HUA(MPa) | KA IKAIKA HOU (MPa) | KA WAIWAI IMAPACT J/℃ | Hana wela °C*h | ||||

| GB/T RULA | 918 | 22 | - | - | ||||

PALAPALA PALAPALA I MANAOIA:

| NĀ KĀNĀWAI (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| UILA (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||