I ke kaʻina hana paʻakikī, hoʻoulu pinepine nā māwae i nā pilikia e like me ka hana hou a me ka hoʻihoʻi ʻana o ka mea kūʻai aku. He ʻokoʻa ka hoʻopaʻa ʻana i ka ihu me ka hoʻoheheʻe ʻia ʻana, a ʻokoʻa hoʻi ka hoʻoholo ʻana a me ka nānā ʻana o nā māwae. Hoʻopili a kūkākūkā kēia ʻatikala i ke ʻano maʻamau o nā māwae i ke kaʻina hana o ka pale ʻana i ka ʻaʻahu.

1. Ka hoʻoholo ʻana o nā māwae

I kēia manawa, ma ka ʻāina a ma ke ao holoʻokoʻa, ʻaʻohe maʻamau maʻamau no nā māwae i hoʻokumu ʻia e ka lole ʻili paʻakikī. ʻO ke kumu nui, ʻo ia ka nui o nā ʻano hana hana no nā huahana ʻaʻahu ʻili paʻakikī, a he paʻakikī ke wehewehe ʻana i nā pae hoʻoholo ʻokoʻa Applicable crack ma lalo o nā kūlana. Eia nō naʻe, e like me ka ʻike i ka hoʻohana ʻana i nā mea hoʻoheheʻe paʻa paʻa i ke alo i nā ʻano ʻano like ʻole, hiki ke hoʻokaʻawale ʻia kekahi mau māwae, a me nā kūlana ʻae i nā ʻoihana like ʻole:

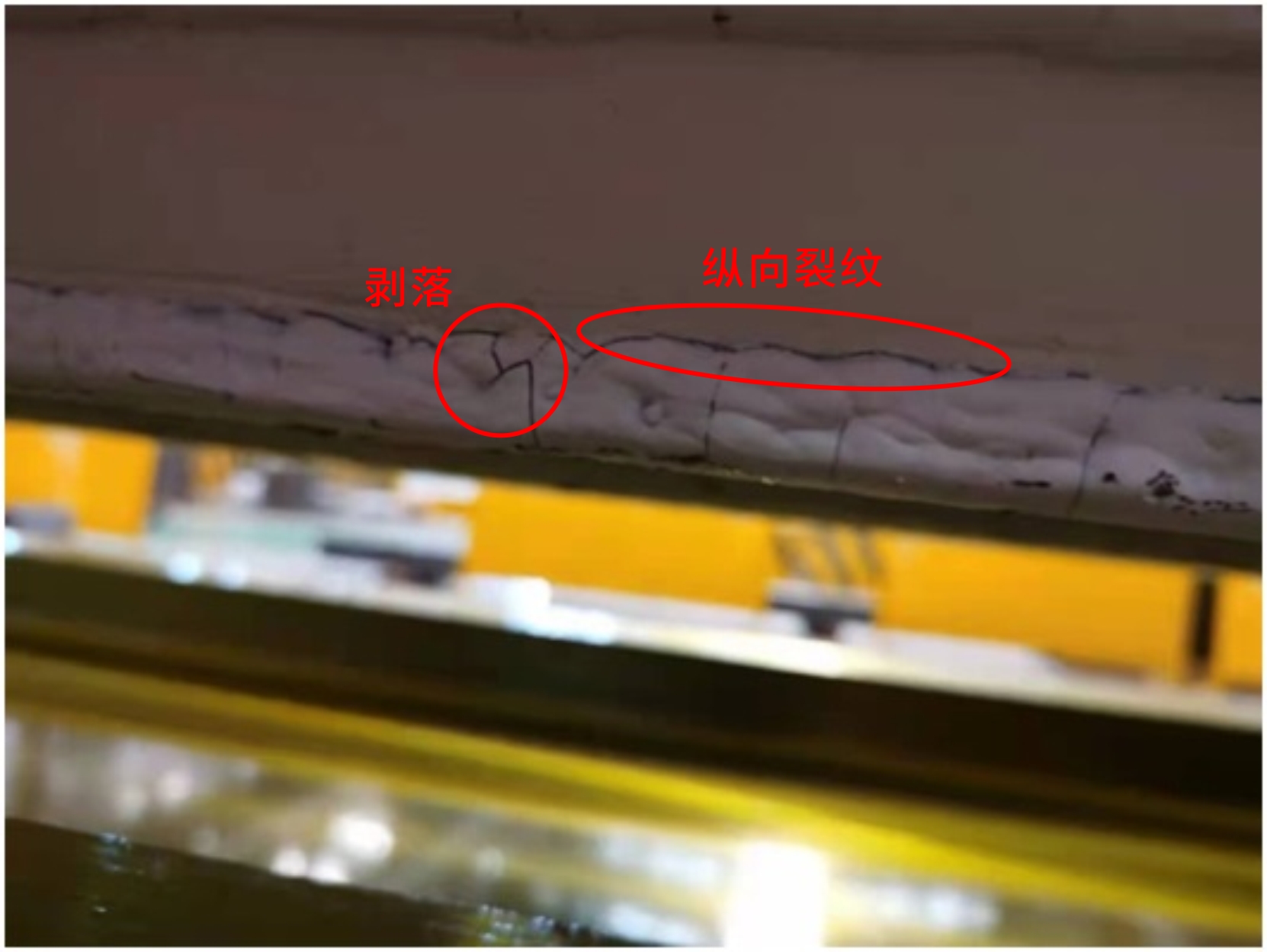

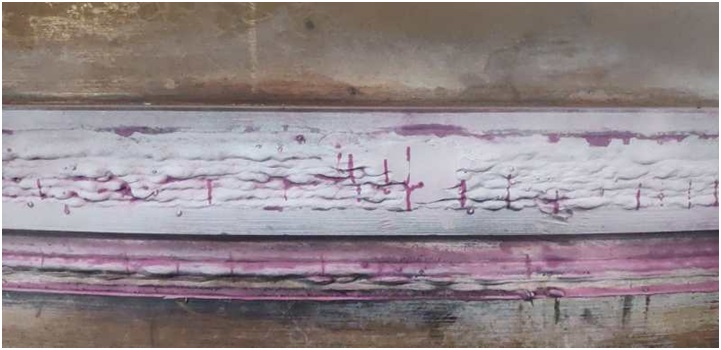

1. Ua like ke kuhikuhi o ka mawae me ka weld bead (longitudinal crack), mau māwae transverse, māwae e hohola ana i ka metala kumu, spalling.

I ka wā e hoʻokō ʻia ai kekahi o nā pae māwae i ʻōlelo ʻia ma luna, aia ka pilikia e hāʻule ka papa i luna holoʻokoʻa. ʻO ke kumu, ʻaʻohe mea o ka noi huahana, ʻaʻole ʻae ʻia a hiki ke hana hou ʻia a kūʻai hou ʻia.

2. Aia wale nā māwae transverse a me ka pau ʻole

No nā mea hana e pili ana me nā mea paʻa e like me ka ʻeleʻele, ke one, a me nā mine lanahu, pono ke kiʻekiʻe ka paʻakikī (HRC 60 a ʻoi aʻe paha), a hoʻohana mau ʻia nā mea wili chromium kiʻekiʻe no ka hoʻoheheʻe ʻana i luna. E hana ʻia nā kristal chromium carbide i hana ʻia i loko o ka weld bead ma muli o ka hoʻokuʻu ʻana i ke kaumaha. Hiki ke ʻae ʻia nā māwae inā pili wale ka ʻaoʻao māwae i ka pahu weld (transverse) a ua hoʻopau ʻia. Eia nō naʻe, e hoʻohana mau ʻia ka helu o nā māwae ma ke ʻano he kuhikuhi e hoʻohālikelike i nā pono a me nā hemahema o nā mea hoʻohana welding a i ʻole nā kaʻina hana i luna.

3. ʻAʻohe māhā weld bead

No nā mea hana e like me nā flanges, valves, a me nā paipu, kahi o nā mea pili nui i ke kinoea a me nā wai, ʻoi aku ka makaʻala o nā koi no nā māwae i loko o ka weld bead, a ʻo ka mea maʻamau ke koi ʻia ʻaʻole i loaʻa nā māwae.

Pono e hoʻoponopono a hana hou ʻia nā māwae liʻiliʻi ma ka ʻili o nā mea hana e like me nā flanges a me nā valve.

E hoʻohana i kā mākou hui GFH-D507Mo valve nā mea hoʻohana wili kūikawā no ka hoʻoulu ʻana, ʻaʻohe māwae ma ka ʻili.

2. ʻO nā kumu nui o ka paʻa ʻana o ka ʻili i nā māwae

Nui nā kumu e hoʻomaka ai nā māwae. No ka paʻa paʻa paʻa ʻana i ka hoʻoheheʻe ʻana i luna, hiki ke hoʻokaʻawale ʻia i nā māwae wela i hiki ke loaʻa ma hope o ka hala mua a i ʻole ka lua, a me nā māwae anu e ʻike ʻia ma hope o ka lua a i ʻole ma hope o ka hoʻopili ʻana.

māwae wela:

I ka wā o ke kaʻina hana hoʻoheheʻe, hoʻomaʻalili ka metala i loko o ka weld seam a me ka wela wela i kahi wela wela kokoke i ka laina solidus e hana i nā māwae.

māwae anu:

ʻO nā māwae i hana ʻia ma nā mahana ma lalo o ka solidus (ma kahi o ka martensitic transformation temperature o ke kila) ka mea nui i loaʻa i nā kila kalapona waena a me nā kila haʻahaʻa ikaika kiʻekiʻe a me nā kila waena.

E like me ka inoa e hōʻike nei, ʻike ʻia nā huahana ʻili paʻa no ko lākou paʻakikī kiʻekiʻe. Eia nō naʻe, ʻo ka ʻimi ʻana i ka paʻakikī i ka mechanics ka hopena i ka emi ʻana o ka plasticity, ʻo ia hoʻi, ka piʻi ʻana o ka brittleness. ʻO ka ʻōlelo maʻamau, ʻaʻole nānā nui ka ʻili ma luna o ka HRC60 i nā māwae wela i hana ʻia i ka wā o ke kaʻina hana kuʻi. Eia naʻe, paʻakikī surfacing kuʻihao me ka paakiki ma waena o HRC40-60, ina he koi no ka mawae, Na intergranular māwae i loko o ka welding kaʻina hana a me ka liquefaction a me multilateral māwae ma muli o ka weld bead luna a hiki i ka wela-pili wahi o ka lalo weld. pilikia loa ka bead.

ʻOiai inā e hoʻomalu maikaʻi ʻia ka pilikia o nā māwae wela, e kū mau ana ka hoʻoweliweli o nā māwae anu ma hope o ka hoʻoheheʻe ʻana i luna, ʻoi aku ka palupalu loa o nā mea e like me ka weld weld bead, ʻoi aku ka maʻalahi o nā māwae anu. ʻO ka māwae koʻikoʻi ka hapa nui o nā māwae anu

3. Nā mea koʻikoʻi e pili ana i nā māwae pale ʻaʻahu ma nā ʻili paʻa a me nā hoʻolālā e pale aku i nā māwae

ʻO nā mea koʻikoʻi e hiki ke ʻimi ʻia i ka wā e puka mai ai nā māwae i loko o ke kaʻina hana ʻaʻahu ʻili paʻakikī e like me kēia, a ua manaʻo ʻia nā hoʻolālā kūpono no kēlā me kēia kumu e hōʻemi ai i ka pilikia o nā māwae:

1. Mea kumu

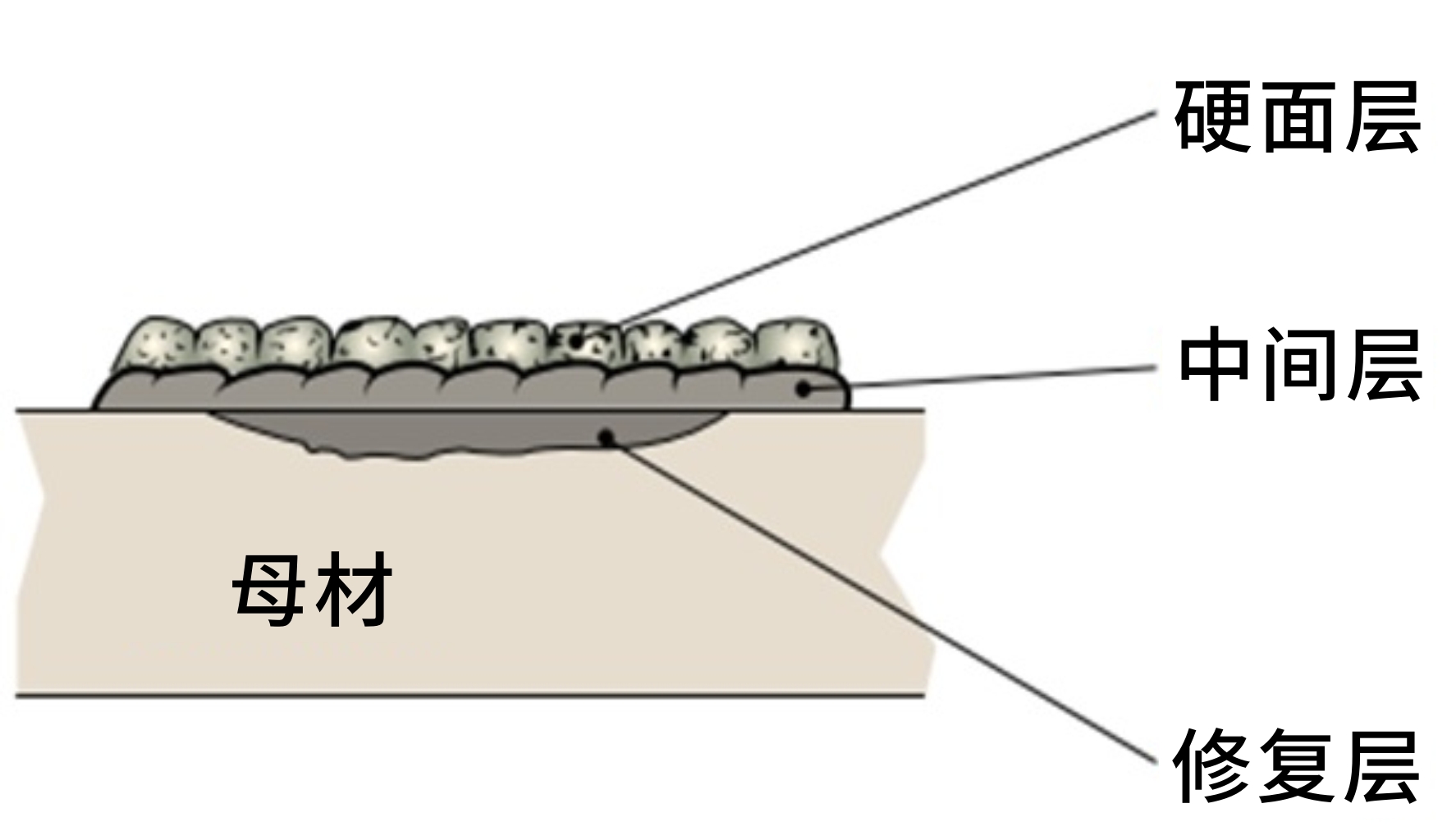

He mea koʻikoʻi loa ka mana o ka metala kumu ma luna o ka ʻili paʻa paʻa, ʻoi aku hoʻi no nā mea hana me ka liʻiliʻi o 2 mau papa o ka hoʻoheheʻe ʻana. Hoʻopili pololei ke ʻano o ka metala kumu i nā waiwai o ka weld bead. ʻO ke koho waiwai kahi kikoʻī e pono e noʻonoʻo ʻia ma mua o ka hoʻomaka ʻana i ka hana. No ka laʻana, inā e uhi ʻia kahi mea hana valve me ka paʻakikī paʻakikī e pili ana i ka HRC30 me kahi mea hao kumu, pono ia e hoʻohana i kahi mea hoʻoheheʻe me ka paʻakikī haʻahaʻa haʻahaʻa, a i ʻole e hoʻohui i kahi papa waena o ke kila kila, i mea e hiki ai. pale i ka maʻiʻo kalapona i loko o ka mea kumu mai ka hoʻonui ʻana i ka pilikia o ka weld bead māwae.

E hoʻohui i kahi papa waena ma luna o ka mea kumu e hōʻemi i ka pilikia o ka pohā

2. Welding consumables

No ke kaʻina hana ʻaʻole pono nā māwae, ʻaʻole kūpono nā mea hoʻohana kiʻekiʻe-carbon a kiʻekiʻe-chromium. Manaʻo ʻia e hoʻohana i nā mea hoʻohana wiliwili martensitic system, e like me kā mākou GFH-58. Hiki iā ia ke wiliwili i ka ʻili o ka bead māwae ʻole ke kiʻekiʻe ka paʻakikī e like me ka HRC58 ~ 60, ʻoi aku ka maikaʻi no nā papa hana non-planar i abrasive loa i ka lepo a me ka pōhaku.

3. Hoʻokomo wela

Hoʻohana ʻia ka hana ma luna o ka pūnaewele e hoʻohana i ke ʻano kiʻekiʻe a me ka uila ma muli o ka hoʻoikaika ʻana i ka pono, akā ʻo ka hoʻohaʻahaʻa haʻahaʻa ʻana i ka manawa a me ka volta hiki ke hōʻemi pono i ka hiki ʻana o nā māwae wela.

4. Hoʻomalu wela

Hiki ke manaʻo ʻia ke ʻano o ka hoʻomau ʻana i ka hoʻomehana ʻana, ka hoʻoluʻu a me ka hoʻomaʻamaʻa hou ʻana no kēlā me kēia kaʻa, no laila he mea nui ka mālama ʻana i ka wela, mai ka hoʻomaʻamaʻa ʻana ma mua o ka wili ʻana a hiki i ka wela i ka wā o ka hoʻokele ʻana, a me ke kaʻina hoʻoluʻu ma hope. wiliwili, pono ka noonoo nui.

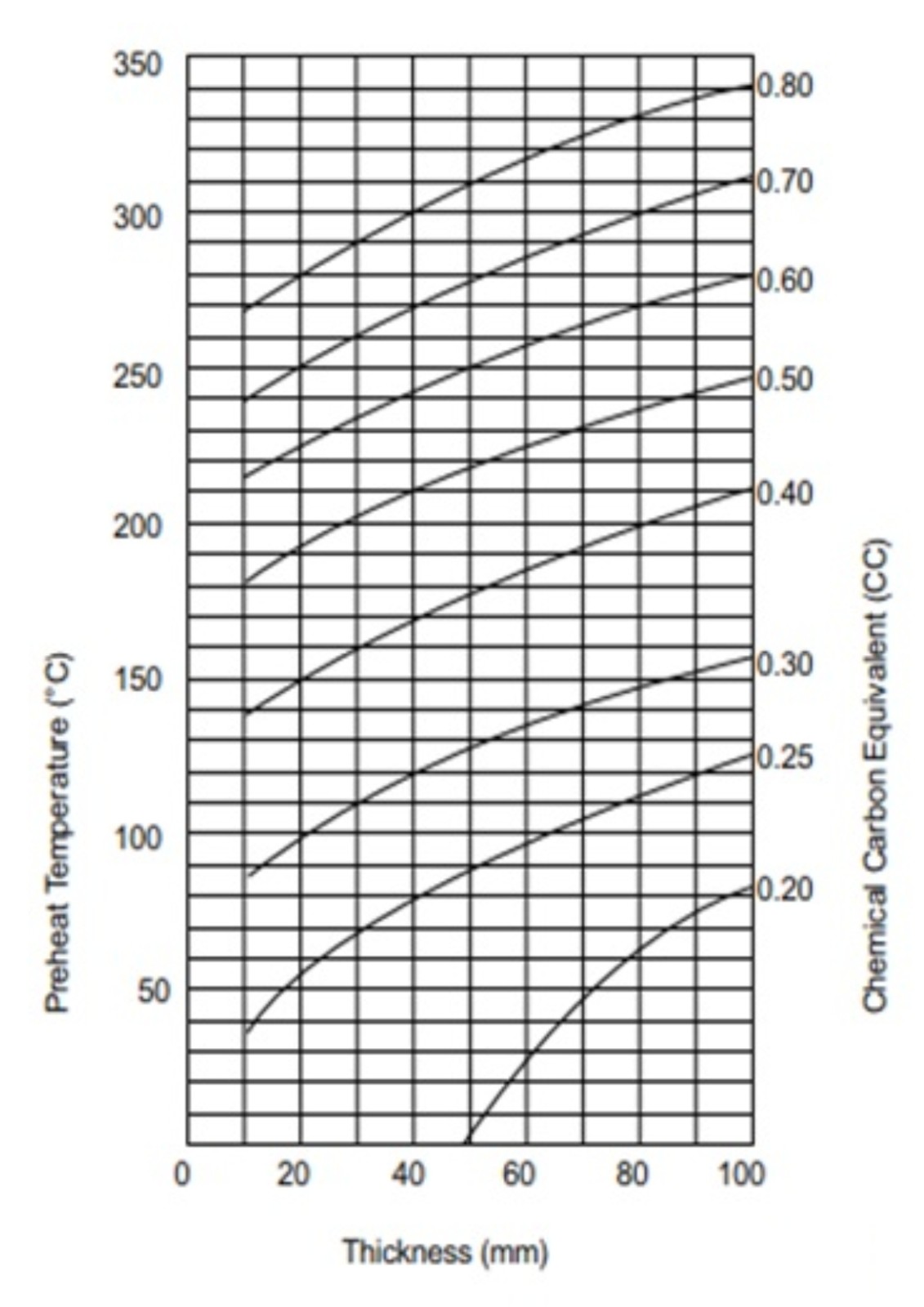

ʻO ka preheating a me ka track wela o ka hoʻoheheʻe ʻana i luna e pili pono i ka ʻike kalapona o ka substrate. Aia ka substrate ma aneʻi i ka mea kumu a i ʻole ka papa waena, a me ka lalo o ka ʻili paʻa. ʻO ka ʻōlelo maʻamau, ma muli o ke kalapona maʻiʻo o ka ʻili paʻa i waiho ʻia inā kiʻekiʻe ka ʻike, pono e mālama i ka mahana o ke alanui ma luna o 200 degere. Eia nō naʻe, ma ka hana maoli, ma muli o ka lōʻihi o ka weld bead, ua hoʻomaha ʻia ka ʻaoʻao mua o ka weld bead i ka hopena o hoʻokahi pass, a ʻo ka lua o ka lua e hana maʻalahi i nā māwae i ka wahi wela o ka substrate. . No laila, i ka nele o nā lako kūpono e mālama ai i ka wela o ke kahawai a i ʻole preheat ma mua o ke kuʻi ʻana, ua ʻōlelo ʻia e hana i nā ʻāpana he nui, nā welds pōkole, a me ka hoʻomau ʻana o ka hoʻoheheʻe ʻana i luna i ka ʻāpana like e mālama i ka wela o ke kahawai.

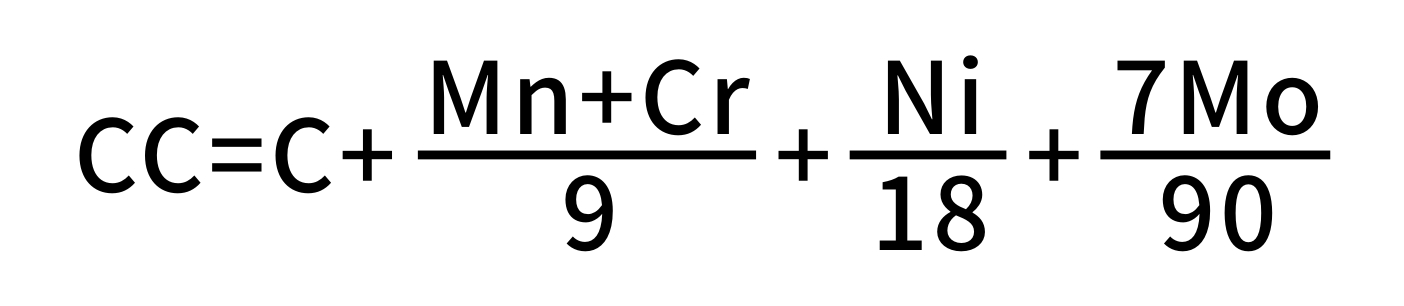

Ka pilina ma waena o ke kalapona a me ka wela preheating

ʻO ka hoʻomaha mālie ma hope o ka hoʻoulu ʻana he hana koʻikoʻi akā mālama ʻole ʻia, ʻoi aku hoʻi no nā mea hana nui. I kekahi manawa ʻaʻole maʻalahi ka loaʻa ʻana o nā lako kūpono e hāʻawi i nā kūlana hoʻomaha mālie. Inā ʻaʻohe ala e hoʻoponopono ai i kēia kūlana, hiki iā mākou ke ʻōlelo hou aku e hoʻohana hou ʻia ʻO ke ʻano o ka hana ʻāpana, a i ʻole ke pale ʻana i ka welding i ka wā haʻahaʻa ka mahana, e hōʻemi i ka pilikia o nā māwae anu.

ʻEhā. Ka hopena

Nui nā ʻokoʻa o kēlā me kēia mea hana i nā koi o ka hardfacing no nā māwae i nā noi kūpono. Hana kēia ʻatikala i kahi kūkākūkā koʻikoʻi ma muli o ka ʻike liʻiliʻi. ʻO kā mākou hui ʻoihana paʻa paʻa paʻa o nā mea hoʻohana wili i nā huahana kūpono i nā mea kūʻai aku e koho ai no nā ʻano paʻakikī a me nā noi. Welina mai e kūkākūkā me ka ʻoihana ma kēlā me kēia apana.

Hoʻohana ʻana i ka hale hana papa hana hoʻopaʻa ʻaʻahu

| 'ikamu | Pale kinoea | nui | Nui | HRC | Ke hoʻohana nei |

| GFH-61-0 | Mālama iā ʻoe iho | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mn:1.2 Kr:28.0 | 61 | He kūpono no ka wili huila, huila sima, bulldozers, etc. |

| GFH-65-0 | Mālama iā ʻoe iho | 1.6 2.8 3.2 | C:5.0 Kr:22.5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 | 65 | He kūpono no ke kiʻekiʻe wela o ka lepo hoʻoneʻe ʻana i nā ʻūhā fan, nā lako hana ʻai i ka umu ahi, etc. |

| GFH-70-O | Mālama iā ʻoe iho | 1.6 2.8 3.2 | C:5.0 Kr:30.0 B:0.3 | 68 | Hoʻopili ʻia i ka huila lanahu, ʻulaʻula ʻuhane, ka loaʻa ʻana o ka mea hana, ka uhi ʻana i ka lanahu, grinder, etc. |

Hoʻohana i ka ʻoihana sima

| 'ikamu | Pale kinoea | nui | Nui | HRC | Ke hoʻohana nei |

| GFH-61-0 | Mālama iā ʻoe iho | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mn:1.2 Kr:28.0 | 61 | He kūpono no ka wili ʻana i nā wili pōhaku, nā huila sima, etc |

| GFH-65-0 | Mālama iā ʻoe iho | 1.6 2.8 3.2 | C:5.0 Kr:22.5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 | 65 | He kūpono no ke kiʻekiʻe wela o ka lepo hoʻoneʻe ʻana i nā ʻūhā fan, nā lako hana ʻai i ka umu ahi, etc. |

| GFH-70-O | Mālama iā ʻoe iho | 1.6 2.8 3.2 | C:5.0 Kr:30.0 B:0.3 | 68 | He kūpono no ka wili ʻana i nā wili pōhaku, nā niho ʻuhane, ka loaʻa ʻana o nā niho, nā mea wili, etc. |

| GFH-31-S | GXH-81 | 2.8 3.2 | C:0.12 Aia:0.87 Mn:2.6 Mo:0.53 | 36 | Pili i nā ʻāpana aahu metala e like me nā huila lei aliʻi a me nā axles |

| GFH-17-S | GXH-81 | 2.8 3.2 | C:0.09 Si:0.42 Mn:2.1 Kr:2.8 Mo:0.43 | 38 | Pili i nā ʻāpana aahu metala e like me nā huila lei aliʻi a me nā axles |

Hoʻohana mea kanu kila

| 'ikamu | Pale kinoea | nui | Nui | HRC | Ke hoʻohana nei |

| GFH-61-0 | Mālama iā ʻoe iho | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mn:1.2 Kr:28.0 | 61 | He kūpono no ka hoʻopaʻa ʻana i nā pahu kapuahi mea kanu, nā niho ʻuhane, nā papa paʻa paʻa, etc. |

| GFH-65-0 | Mālama iā ʻoe iho | 1.6 2.8 3.2 | C:5.0 Kr:22.5 Mo:3.2 V:1.1 W:1.368 Nb:3.5 | 65 | |

| GFH-70-0 | Mālama iā ʻoe iho | 1.6 2.8 3.2 | C:5.0 Kr:30.0 B:0.3 | 68 | |

| GFH-420-S | GXH-81 | 2.8 3.2 | C:0.24 Aia:0.65 Mn:1.1 Kr:13.2 | 52 | He kūpono no ka hoʻolei ʻana i nā ʻōwili, ka lawe ʻana i nā ʻōwili, nā ʻōwili hoʻokele, a me nā mea ʻē aʻe i nā mea kanu hoʻolei mau a me nā mea kanu wela. |

| GFH-423-S | GXH-82 | 2.8 3.2 | C:0.12 Si:0.42 Mn:1.1 Kr:13.4 Mo:1.1 V:0.16 Nb:0.15 | 45 | |

| GFH-12-S | GXH-81 | 2.8 3.2 | C:0.25 Aia:0.45 Mn:2.0 Kr:5.8 Mo:0.8 V:0.3 W:0.6 | 51 | ʻO nā waiwai ʻaʻahu anti-adhesive, kūpono i nā ʻōwili hoʻokele hale paʻa kila, nā ʻōwili a me nā ʻāpana ʻāpana ma waena o nā metala. |

| GFH-52-S | GXH-81 | 2.8 3.2 | C:0.36 Si:0.64 Mn:2.0 Ni:2.9 Kr:6.2 Mo:1.35 V:0.49 | 52 |

Noi Miner

| 'ikamu | Pale kinoea | nui | Nui | HRC | Ke hoʻohana nei |

| GFH-61-0 | Mālama iā ʻoe iho | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mn:1.2 Kr:28.0 | 61 | E pili ana i nā excavators, nā alanui, nā koho, etc. |

| GFH-58 | CO2 | 1.6 2.4 | C:0.5 Si:0.5 Mn:0.95 Ni:0.03 Kr:5.8 Mo:0.6 | 58 | He kūpono no ka hoʻoheheʻe ʻana i luna ma ka ʻaoʻao o ke ala lawe pōhaku |

| GFH-45 | CO2 | 1.6 2.4 | C:2.2 Si:1.7 Mn:0.9 Cr:11.0 Mo:0.46 | 46 | He kūpono no ke komo ʻana i nā ʻāpana ma waena o nā metala |

Ka hoʻohana ʻana i ka valve

| 'ikamu | Pale kinoea | nui | Nui | HRC | Ke hoʻohana nei |

| GFH-D507 | CO2 | 1.6 2.4 | C:0.12 S:0.45 Mn:0.4 Ni:0.1 Kr:13 Mo:0.01 | 40 | He kūpono no ka hoʻoheheʻe ʻana i ka ʻili o ka ili hoʻopaʻa valve |

| GFH-D507Mo | CO2 | 1.6 2.4 | C:0.12 S:0.45 Mn:0.4 Ni:0.1 Kr:13 Mo:0.01 | 58 | He kūpono no ka hoʻoheheʻe ʻana o nā kiwi me ka corrosiveness kiʻekiʻe |

| GFH-D547Mo | Nā lāʻau lima | 2.6 3.2 4.0 5.0 | C:0.05 Mn:1.4 Si:5.2 P:0.027 S:0.007 Ni:8.1 Kr:16.1 Mo:3.8 Nb:0.61 | 46 | He kūpono no ke kiʻekiʻe wela, kiʻekiʻe puʻe kiwi puʻupuʻu surfacing welding |

More information send to E-mail: export@welding-honest.com

Ka manawa hoʻouna: Dec-26-2022