I. Nānā

Me ka hoʻomohala wikiwiki ʻana o ka hana ʻoihana mīkini, ke ulu nei nā hale welded e like me ka ʻenekinia hou a me nā moku kaomi i nā ʻano nui a māmā. ʻO nā koi no nā māka ikaika kila ke piʻi aʻe a kiʻekiʻe, ʻaʻole wale e koi ana i nā waiwai mechanical piha maikaʻi, akā maikaʻi nō hoʻi ka processability, weldability a me ka pale ʻana.

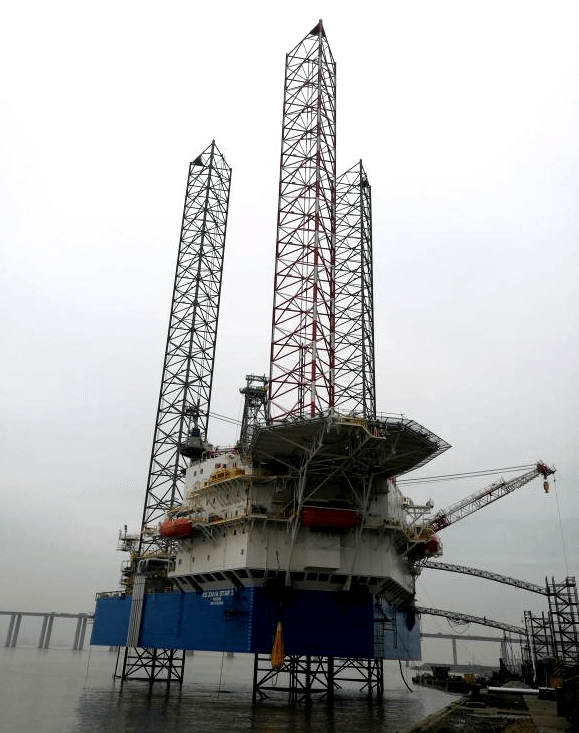

ʻO ke kila Q690 ka mea kila kiʻekiʻe welded structural steel, kahi e kū ai ʻo Q no ka hua, a ʻo 690 ke ʻano o ka pae ikaika o ka hua he 690MPa. 690MPa papa kila he kiʻekiʻe ka hua a me ka ikaika tensile, a ua hoʻohana nui ʻia i nā mīkini eli lanahu, nā mīkini hana, ʻenehana moana, nā kahua o waho, nā moku kaomi, a me nā mea ʻē aʻe, e koi ana i ke kila e loaʻa i ka ikaika hua kiʻekiʻe a me ka palena luhi, ka paʻakikī hopena maikaʻi, Cold. formability a maikai weldability.

2. Hoʻopuka pōkole o ka pā kila Q690

| International Q690 kila kila | Q690A | Q690B | Q690C | Q690D | Q690E | Q690F |

| huluhulu | ʻōwili wela | Quenching + tempering (quenched and tempered state) | ||||

| maʻiʻo haumia | P/S kiʻekiʻe | haahaa P/S | P/S liʻiliʻi loa | |||

| Nā Koina Haʻalulu | NO | Haʻalulu wela maʻamau | 0 ℃ | -20 ℃ | -40 ℃ | -60 ℃ |

Eia nō naʻe, i kēia manawa, ʻo ka pā kila 690MPa no nā kīʻaha kīʻaha kūloko e hoʻokumu nui ʻia ma ka European standard EN10028-6, a ua helu pōkole ʻia nā waiwai pili i ka papa aʻe.

| Hāʻawi i ke kila 690MPA no nā mea paʻi maʻamau o ʻEulopa | P690Q | P690QH | P69QL1 | P69QL2 |

| huluhulu | ka palaoa kinai a me ke kila wela | |||

| koi ikaika | Hua≥690MPa(pā mānoanoa≤50mm) Tensile770-940MPa | |||

| maʻiʻo haumia | P≤0.025%, S≤0.015% | P≤0.02%, S≤0.010% | ||

| Nā Koina Haʻalulu | 20 ℃≥60J | 20 ℃≥60J | 0℃≥60J | -20 ℃≥40J |

| 0℃≥40J | 0℃≥40J | -20 ℃≥40J | -40 ℃≥27J | |

| -20 ℃≥27J | -20 ℃≥27J | -40 ℃≥27J | -60 ℃≥27J | |

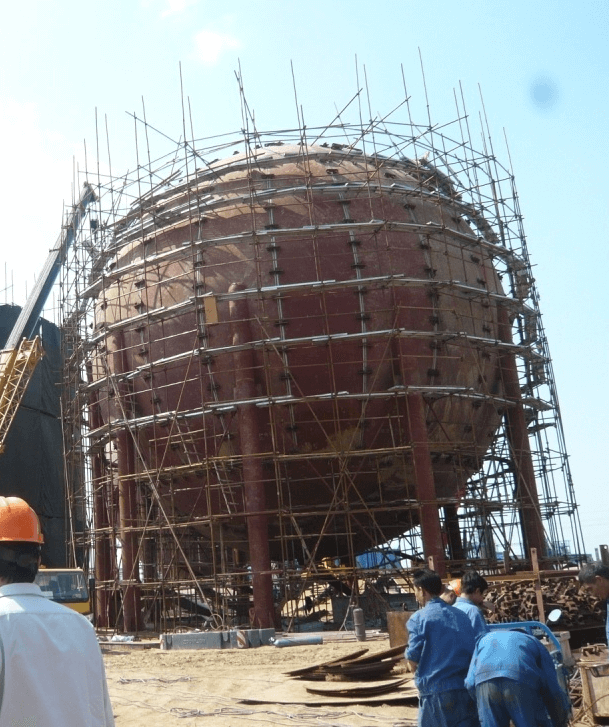

| Nā wahi noi nui | ʻO nā hale paʻi a i ʻole nā moku kaomi me nā koi haʻahaʻa haʻahaʻa | ʻO ka pahu spherical me nā koi ʻenehana kiʻekiʻe | pahu wai kai wai wai | |

Ma ke ʻano he pā kila no ka mālama ʻana i nā pahu a me ka hiki ke kaomi, pono ke loaʻa ka ikaika maikaʻi a me ka paʻakikī, ka hana ʻana i ke anu anuanu a me ka naʻau haʻahaʻa haʻahaʻa. ʻOiai ʻo ke kila Q690 i hoʻopaʻa ʻia a hoʻonāuki ʻia he haʻahaʻa haʻahaʻa carbon equivalent a maikaʻi loa nā waiwai piha, aia nō ia i kahi ʻano paʻakikī e hoʻohālikelike ʻia me nā mea hao 50/60kg ʻē aʻe, a koi ʻia ka mālama wela post-weld. Eia nō naʻe, ua hōʻike ʻia ka nui o nā haʻawina hoʻokolohua no ka Q690 steel welding consumables, ʻo ka haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa e hoʻohaʻahaʻa nui ʻia ma hope o ka mālama ʻana i ka wela, a me ka piʻi ʻana o ka wela wela a me ka emi ʻana o ka wela hopena, ka deterioration. o ka welding consumable toughness e oi maopopo. No laila, he mea koʻikoʻi nui ka hoʻomohala ʻana i ka ikaika kiʻekiʻe, ka paʻakikī paʻakikī, a me nā koʻokoʻo hoʻoheheʻe wela no ke kila Q690 e hoʻopili pono ai i ke kila Q690 i nā lako paʻi, hoʻemi i nā mea kila, a hoʻemi i nā kumukūʻai hana.

3.Brief hoʻolauna o kā mākou Q690 kila kuʻihao koʻokoʻo

| 'ikamu | Kūlana | ʻAno ʻili | Polarity | nā hiʻohiʻona nui |

| GEL-118M | AWS A5.5 E1108MISO 18275-BE7618-N4M2A | Pauka hao ʻano hydrogen haʻahaʻa | DC+/AC | ʻO ka ikaika kiʻekiʻe, ka hydrogen haʻahaʻa, ka maikaʻi deposition kiʻekiʻe, nā waiwai mechanical paʻa, maikaʻi loa ka hopena haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa i -50 ° C, a me ka paʻakikī hopena maikaʻi ma -40 ° C ma hope o ka mālama wela. |

| GEL-758 | AWS A5.5 E11018-GISO 18275-BE7618-G A | Pauka hao ʻano hydrogen haʻahaʻa | DC+/AC | ʻO ka hydrogen haʻahaʻa haʻahaʻa, ʻoi aku ka maikaʻi o ka deposition kiʻekiʻe, ka paʻakikī kiʻekiʻe (-60 ℃≥70J), ka paʻakikī hopena maikaʻi ma -40/-50 ℃ ma hope o ka mālama wela |

| GEL-756 | AWS A5.5 E11016-GISO 18275-BE7616-G A | ʻAno haʻahaʻa hydrogen potassium | AC/DC+ | ʻO ka hydrogen haʻahaʻa haʻahaʻa, AC/DC+ ʻelua-kumu, paʻakikī hopena kiʻekiʻe (-60 ℃≥70J), paʻakikī hopena maikaʻi ma -50/-60 ℃ ma hope o ka mālama wela |

4.Q690 kila kuʻihao koʻokoʻo mechanical hana hōʻike

| 'ikamu | As-welded mechanical properties | ||||||

| Hāʻawi MPA | ʻO MPA ʻuʻuku | Hooloihi % | Ka waiwai hopena J/℃ | ʻO ka hoʻāʻo radiographic | Hiki ke hoʻoheheʻe ʻia Ml/100g | ||

| -50 ℃ | -60 ℃ | ||||||

| AWS A5.5 E11018M | 680- 760 | ≥760 | ≥20 | ≥27 | - | I | - |

| ISO 18275-B E7618-N4M2A | 680- 760 | ≥760 | ≥18 | ≥27 | - | I | - |

| GEL-118M | 750 | 830 | 21.5 | 67 | 53 | I | 3.2 |

| AWS A5.5 E1101X-G | ≥670 | ≥760 | ≥15 | - | - | I | - |

| ISO 18275B E761X-GA | ≥670 | ≥760 | ≥13 | - | - | I | - |

| GEL-758 | 751 | 817 | 19.0 | 90 | 77 | I | 3.4 |

| GEL-756 | 764 | 822 | 19.0 | 95 | 85 | I | 3.6 |

Hōʻike:

1. ʻO ka "X" i kaha ʻia i ka ʻulaʻula ma ka American Standard a me ka European Standard e hōʻike ana i ke ʻano o ka ʻili lāʻau.

2. E pili ana ka GEL-758 me E11018-G a me ISO 18275-B E7618-G A ma AWS a me nā kūlana ISO.

3. E pili ana ka GEL-756 me E11016-G a me ISO 18275-B E7616-G A ma nā kūlana AWS a me ISO.

Mechanical waiwai o Q690 kila kuʻihao koʻokoʻo ma ka wela wela moku'āina

| 'ikamu | Mechanical waiwai o ka wela wela | ||||||

| Hāʻawi MPA | ʻO MPA ʻuʻuku | Hooloihi % | Ka waiwai hopena J/℃ | Pumehana ℃*h | |||

| -40 ℃ | -50 ℃ | -60 ℃ | |||||

| Pahuhopu papahana | ≥670 | ≥760 | ≥15 | ≥60 | ≥52 | ≥47 | 570*2 |

| GEL-118M | 751 | 827 | 22.0 | 85 | 57 | - | 570*2 |

| GEL-758 | 741 | 839 | 20.0 | 82 | 66 | 43 | 570*2 |

| GEL-756 | 743 | 811 | 21.5 | 91 | 84 | 75 | 570*2 |

Hōʻike:

1. ʻAʻole loaʻa i nā kūlana pili i ka AWS a me ISO nā koi hana mālama wela no nā huahana i luna. Ua hōʻuluʻulu ʻia nā hana wela ma luna ma muli o nā kūlana ʻenehana o ka hapa nui o nā mea kūʻai aku a no ka ʻike wale nō.

2. ʻO GEL-118M ka hopena maikaʻi loa ma -40 ° C ma hope o ka hoʻomaʻamaʻa wela, a ʻoi aku ka maopopo o ka hopena o ka hopena ma -50 ° C.

3. Ma hope o ka mālama ʻana i ka wela, loaʻa iā GEL-758 ka hopena maikaʻi loa i ka -40 ° C, ʻoi aku ka maikaʻi o ka paʻakikī ma -50 ° C, a me ka hōʻino ʻana i ka haʻahaʻa haʻahaʻa ma -60 ° C.

4. ʻO ka haʻahaʻa haʻahaʻa haʻahaʻa hopena toughness deterioration o GEL-756 ma hope o ka wela hoʻomaʻamaʻa mea liʻiliʻi, a me ka haʻahaʻa-mehana toughness ma -60 ° C ua maikaʻi.

Weldability hōʻike o Q690 kila kuʻihao koʻokoʻo

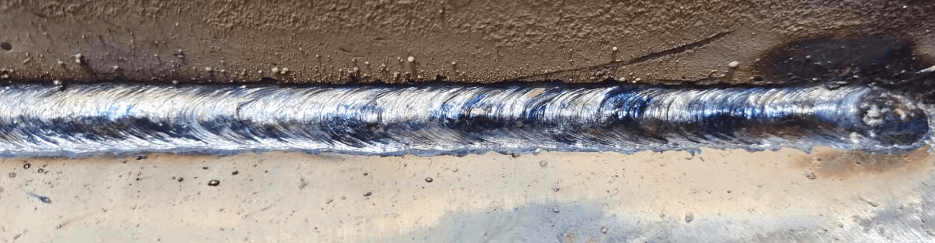

1.Flat fillet welding (φ4.0mm)

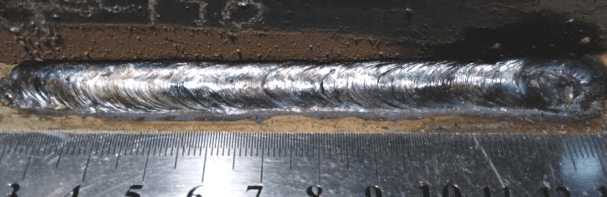

ʻO GEL-118M ka hoʻoheheʻe ʻia ʻana ma mua a ma hope o ka wehe ʻana i ka slag (DC+)

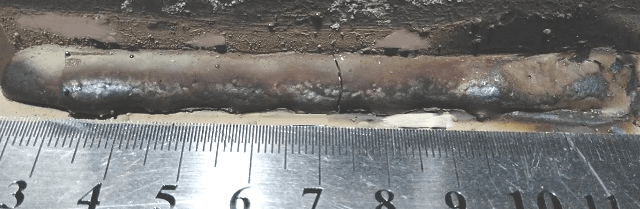

Ma mua a ma hope o ka wehe ʻana o ka slag fillet flat fillet GEL-758 (DC+)

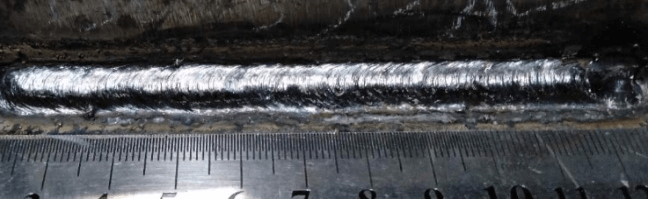

ʻO GEL-756 wiliwili paʻa paʻa ma mua a ma hope o ka wehe ʻana i ka slag (AC)

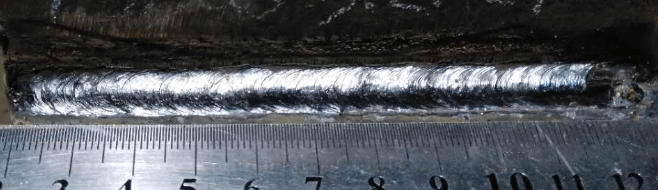

ʻO GEL-756 ka hoʻoheheʻe ʻia ʻana ma mua a ma hope o ka wehe ʻana o ka slag (DC+))

Q690 kila kuʻi koʻokoʻo kuʻihao e mālama

1. Ka mālama ʻana i nā mea hoʻohana welding:

Manaʻo ʻia nā mea hoʻohana welding e mālama ʻia ma lalo o ka mahana mau a me nā kūlana maloʻo, a kau ʻia ma luna o nā pallets a i ʻole nā papa, e pale aku i ka hoʻopili pololei ʻana me nā paia a me ka lepo.

2. Hoʻomākaukau ma mua o ke kuʻi ʻana:

E hoʻomaʻemaʻe loa i ka makū, ka ʻōpala, nā ʻili ʻaila, a me nā mea ʻē aʻe ma luna o ka ʻili o ka mea kumu, a pale i ka makū o ka ʻili a i ʻole ka ʻike ʻana i ka ua a me ka hau.

3. Nā ana pale makani:

I ka wā e wili ai, pono e hōʻoia i ka wikiwiki o ka makani ma ka wahi kuʻi ʻana ʻaʻole ma mua o 2m / s. A i ʻole, pono e lawe ʻia nā hana pale.

4. Hoʻomaʻamaʻa mua:

Manaʻo ʻia e hoʻohana i nā mea hoʻomehana uila e hoʻomehana i ka mea hana ma luna o 150 ° C ma mua o ke kuʻi ʻana. ʻOiai ma mua o ka hoʻoheheʻe ʻana, pono e hoʻomehana ʻia ma luna o 150 ° C.

5. Layer a me alanui ka wela wela:

I loko o ke kaʻina hana hoʻoheheʻe holoʻokoʻa, ʻaʻole pono ka haʻahaʻa haʻahaʻa o ka interpass ma mua o ka wela preheating, a ʻo ka mahana i ʻōlelo ʻia he 150-220 ° C.

6. Hoʻokuʻu ʻia ka hydrogen ma hope o ke kuʻi ʻana:

Ma hope o ka wili ʻia ʻana o ka weld seam, e hoʻonui koke i ka mahana o ka hoʻomehana uila i 250 ℃ ~ 300 ℃, mālama i ka mahana no 2 a 4 mau hola, a laila hoʻomaha mālie.

① Inā ʻo ≥50mm ka mānoanoa o ka mea hana, pono e hoʻonui ʻia ka manawa paʻa i 4-6 mau hola, a laila hoʻomaha mālie.

② Ma lalo o nā kūlana o ka mānoanoa nui a me ke kaohi nui, hiki ke hoʻohui ʻia hoʻokahi dehydrogenation ma hope o ke kuʻi ʻana i ka mānoanoa 1/2, a hoʻomaha mālie i ka mahana interpass.

7. Hoʻolālā papahele:

Manaʻo ʻia e hoʻohana i ka welding multi-layer a me multi-pass, a pono e mālama ʻia ka wikiwiki o ka welding i ka wikiwiki mau.

More information send to E-mail: export@welding-honest.com

Ka manawa hoʻouna: Jan-10-2023