ʻO nā kila hao liʻiliʻi ʻo Flux cored wire ER80S-G Soldering making

KOMPONO KIMIKA:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULA | 0.12 | 0.80-1.50 | 0.30-0.90 | 1.00-1.60 | - | 0.40-0.65 | 0.03 | 0.03 | 0.40 |

| NA RULA AWS | - | - | - | - | - | - | - | - | - |

| KA WAIWAI LA'ANA | 0.105 | 1.00 | 0.60 | 1.25 | 0.03 | 0.5 | 0.01 | 0.005 | 0.05 |

WAIWAI MECHANICAL:

| WAIWAI | IKAIKA HUA(MPa) | KA IKAIKA HOU (MPa) | KA WAIWAI IMAPACT J/℃ | ELONGATION(%) | Hana wela°Cxh | |||||

| GB/T RULA | 470 | 550 | - | 17 | 690*1 | |||||

| NA RULA AWS | 470 | 550 | - | 15 | 690*1 | |||||

| KA WAIWAI LA'ANA | 489 | 609 | 109/0 | 26 | 690*1 | |||||

PALAPALA PALAPALA I MANAOIA:

| NĀ KĀNĀWAI (mm) | 1.0 | 1.2 | 1.6 | |||||||

| UILA (Amp) | H/W | 50-220 | 80-350 | 170-550 | ||||||

| O/W | 50-120 | 80-150 | - | |||||||

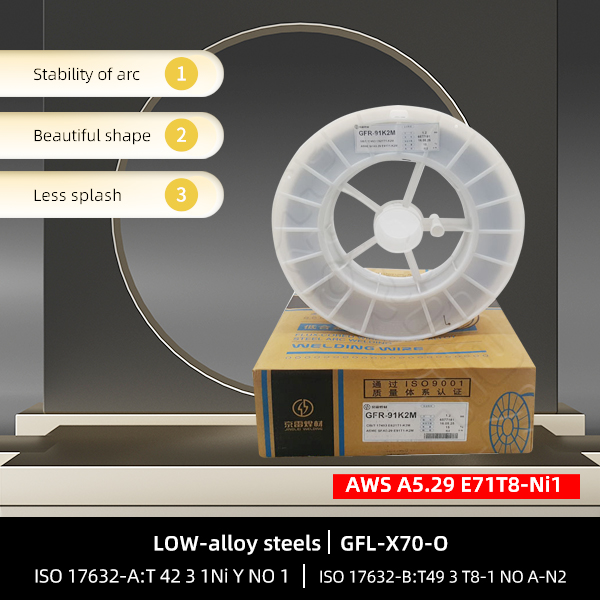

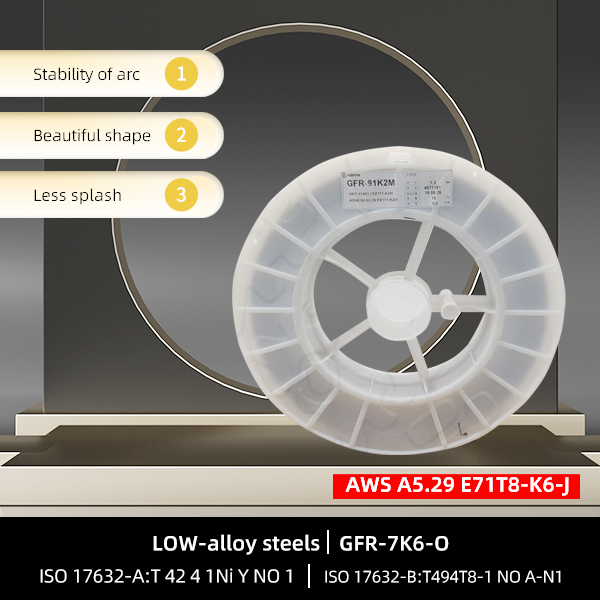

uea kuʻihao pale kinoea no 550MPa papa wela ke kila.

ʻO ka hānai uea maʻemaʻe, kūpaʻa arc, nani ka hana ʻana, maikaʻi ke kahe ʻana o ka hao i hoʻoheheʻe ʻia, ka ʻenehana hoʻoheheʻe maikaʻi loa.

Loaʻa i ka metala fused nā waiwai mechanical maikaʻi, kiʻekiʻe Mn maʻiʻo, kūpaʻa porosity maikaʻi a me ka hana weld.

-

ʻO Mei Jin Hua Sheng ethylene glycol hale kiaʻi synthetic

-

Nā mea wiliwili no nā kaʻa kaʻaahi

-

PX1212 H paepae lako moku

KOMPONO KIMIKA:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULA | 0.12 | 0.80-1.50 | 0.30-0.90 | 1.00-1.60 | - | 0.40-0.65 | 0.03 | 0.03 | 0.40 |

| NA RULA AWS | - | - | - | - | - | - | - | - | - |

| KA WAIWAI LA'ANA | 0.105 | 1.00 | 0.60 | 1.25 | 0.03 | 0.5 | 0.01 | 0.005 | 0.05 |

WAIWAI MECHANICAL:

| WAIWAI | IKAIKA HUA(MPa) | KA IKAIKA HOU (MPa) | KA WAIWAI IMAPACT J/℃ | ELONGATION(%) | Hana wela°Cxh | |||||

| GB/T RULA | 470 | 550 | - | 17 | 690*1 | |||||

| NA RULA AWS | 470 | 550 | - | 15 | 690*1 | |||||

| KA WAIWAI LA'ANA | 489 | 609 | 109/0 | 26 | 690*1 | |||||

PALAPALA PALAPALA I MANAOIA:

| NĀ KĀNĀWAI (mm) | 1.0 | 1.2 | 1.6 | |||||||

| UILA (Amp) | H/W | 50-220 | 80-350 | 170-550 | ||||||

| O/W | 50-120 | 80-150 | - | |||||||

E kākau i kāu leka ma aneʻi a hoʻouna mai iā mākou