490Mpa Electrode lima no ke kila ikaika kiʻekiʻe

Hoʻohana&Maʻamau&Memo

1. He kūpono no ka wili ʻana i ka hao kalapona a me ka hao haʻahaʻa haʻahaʻa, a me ka ikaika like o ka paila, pipeline, kaʻa, hale, alahaka a me nā mea hana ʻē aʻe, e like me Q345.

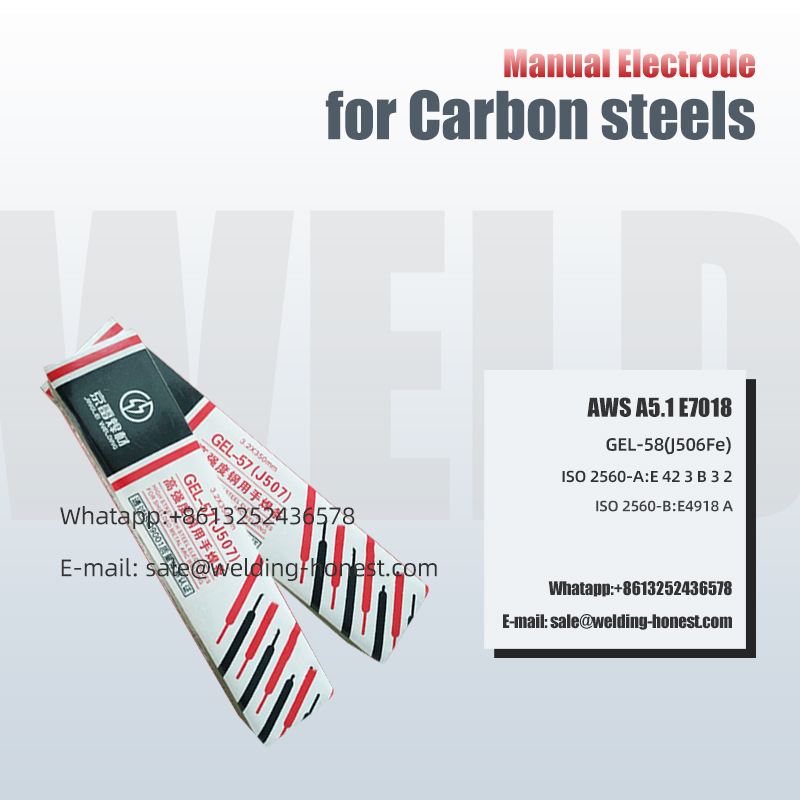

2. ʻO ka maʻamau a mākou i hālāwai ai: GB / T5117 E5018, AWS A5.1 E7018 & A5.1M E4918, ISO2560-A: E 42 3 B 3 2, ISO 2560-B: E4918 A

No ka mea e hoʻopili maʻalahi ka electrode E7018 i ka makū, mālama ʻia i ka umu hoʻomaloʻo electrode. Hiki ke hoʻopaʻa ʻia ka electrode i mālama ʻia i ka lewa ma 350 ~ 400 ℃ no 1h ~ 2h. I mea e hoihoi hou ai i na waiwai o ka ili. Hiki ke wili ʻia ke kila māmā me nā electrodes E7018 unbaked, akā ʻaʻole i lawa ka ikaika weld hope.

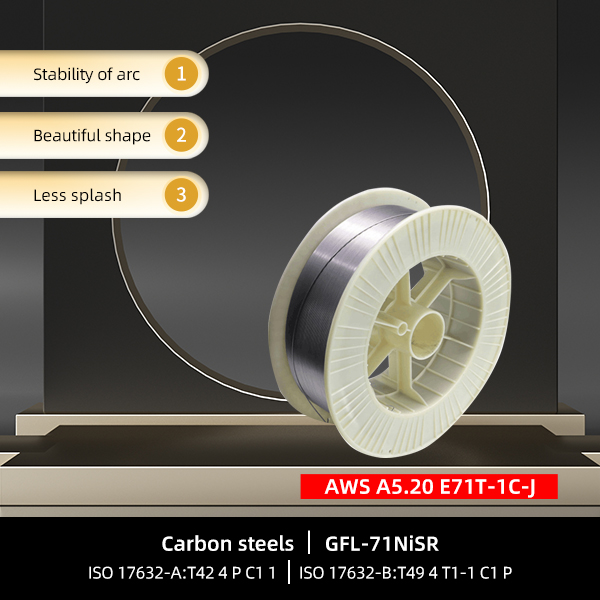

Nā hiʻohiʻona

ʻO ka hao pauka haʻahaʻa hydrogen ʻano lima electrode, kiʻekiʻe kuʻihao maikaʻi, kūpaʻa arc, nani hoʻokumu, corrugations, liʻiliʻi splash, maʻalahi de-slagging, maikaʻi lāʻau lapaʻau ili ahi kū'ē, maikai stomatal kū'ē. ʻO nā waiwai mechanical paʻa, ka plasticity maikaʻi a me ka ikaika haʻahaʻa o ka wela.

ʻO E7018 kahi kiʻekiʻe kiʻekiʻe carbon steel electrode me ka pauka hao haʻahaʻa hydrogen potassium coating. He maikaʻi ke kaʻina hana kuʻi ʻana o ka electrode, ʻoi aku ka maikaʻi o ke arc stiffness, ʻaʻole maʻalahi ka hana ʻana i ka hoʻoheheʻe ʻana i ka hoʻoheheʻe ʻana, hoʻoheheʻe ʻia ke kuʻi ʻana i ka maʻemaʻe maikaʻi a nani hoʻi, liʻiliʻi ka splash, maʻalahi ka slag; ʻO ka weld metala he maikaʻi a paʻa ka haʻahaʻa haʻahaʻa haʻahaʻa a me ke kūʻē ʻana. ʻO ka hoʻohana ʻelua ʻo Ac a me DC, hiki ke hoʻokau i ke kūlana holoʻokoʻa. ʻO kona hiʻohiʻona ʻo ka ʻili lāʻau i loko o ka pauka hao, hiki ke hoʻemi i ka helu o nā papa kuʻi. E hoʻomoʻa i ka electrode ma 350 ~ 400 degere Celsius no 1 ~ 2 mau hola, a hoʻohana me ka baking. ʻO ka maʻamau, hoʻohana ʻia kēia electrode kiʻekiʻe no ka hoʻopaʻa ʻana i ke kila moku (A, B, D a i ʻole E, A36, E36) a me nā hale koʻikoʻi o ke kila haʻahaʻa haʻahaʻa o ka ikaika like, e like me nā boilers, nā moku kaomi a me nā kahua hoʻoheheʻe waho. etc.

Hui & Hale Hana

ʻO ka hoʻohui ʻana o ka huahana a me ka hoʻokomo ʻana i nā waiwai mechanical

KOMPONO KIMIKA:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULA | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| NA RULA AWS | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| KA WAIWAI LA'ANA | 0.075 | 1.17 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

WAIWAI MECHANICAL:

| WAIWAI | IKAIKA HUA(MPa) | KA IKAIKA HOU (MPa) | HEATTREAMENT℃xh | ELONGATION(%) | ||||||

| GB/T RULA | 400 | 490 | AW | 20 | ||||||

| NA RULA AWS | 400 | 490 | AW | 22 | ||||||

| KA WAIWAI LA'ANA | 460 | 555 | AW | 30 | ||||||

PALAPALA PALAPALA I MANAOIA:

| NĀ KĀNĀWAI (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| UILA | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

MANAʻO:

H/W: kuʻekuʻe wāwae kūlana

O/W: wiliwili kūlana ma luna o ke poʻo

Nā hihia maʻamau

Palapala

ʻO ka hoʻohui ʻana o ka huahana a me ka hoʻokomo ʻana i nā waiwai mechanical

KOMPONO KIMIKA:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULA | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| NA RULA AWS | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| KA WAIWAI LA'ANA | 0.075 | 1.17 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

WAIWAI MECHANICAL:

| WAIWAI | IKAIKA HUA(MPa) | KA IKAIKA HOU (MPa) | HEATTREAMENT℃xh | ELONGATION(%) | ||||||

| GB/T RULA | 400 | 490 | AW | 20 | ||||||

| NA RULA AWS | 400 | 490 | AW | 22 | ||||||

| KA WAIWAI LA'ANA | 460 | 555 | AW | 30 | ||||||

PALAPALA PALAPALA I MANAOIA:

| NĀ KĀNĀWAI (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| UILA | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

MANAʻO:

H/W: kuʻekuʻe wāwae kūlana

O/W: wiliwili kūlana ma luna o ke poʻo